Volumetric Modules

Volumetric and modular rooms are becoming widely used for buildings that have a repetitive nature. Common structures include:

- Hotels

- Apartments

- Student accommodation

- Schools

- Hospitals

The benefits of being able to manufacture the complete unit in the factory (including the bathrooms and fitting of furniture) are:

- No weather delays

- Superior finish quality

- All the electrical and plumbing works are done in a controlled atmosphere

- The rooms are sealed before moving to site restricting unauthorized access

Machines and Modular building process

Machines

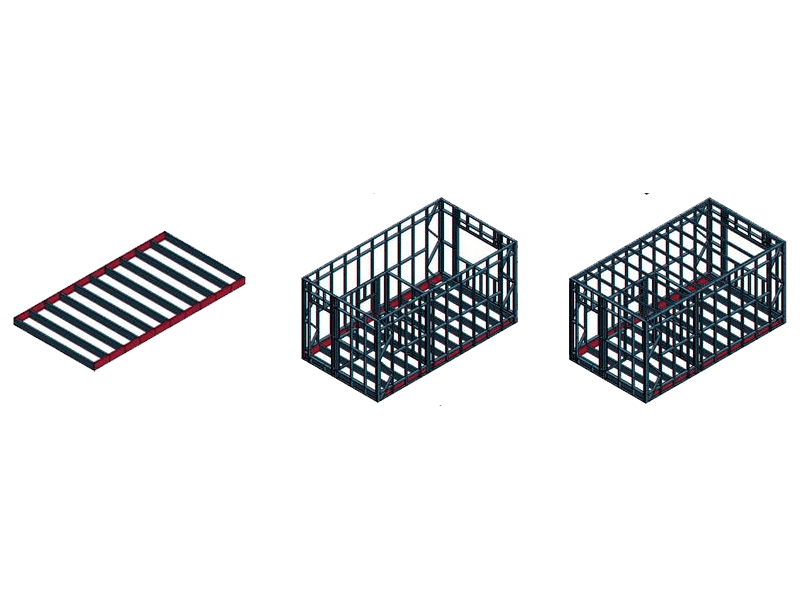

Successful volumetric units require two different sections. The walls and ceiling can be produced using Howick framing machines. There are several buildings build up to 11 floors using the FRAMA 5600 machines due to Howick’s end-bearing detail. The cassette floors can be produced using the FRAMA 6800 floor joist machine.

Machines and Modular building process

Modular building process

Once the building design has been completed and the individual modules specified, the framing components can be made on a just in time basis for site delivery.

A typical assembly process would consist of:

- The FRAMA 6800 floor cassette is rolled and the flooring boards are attached along with the required insulation and services.

- The wall and ceiling frames are assembled.

- The internal lining is fitted and painted.

- The wall frames are then attached to the floor cassette.

- The ceiling frames are then fitted.

- The bathroom can then be fitted and plumbed as well as the electrical fittings and wiring.

- The wall and ceiling insulation is added to the frame.

- The fit-out can then be completed to the desired specification.

- A hotel module for example would feature: carpets, bed, bedside furniture, desk, wardrobe, TV system, air-conditioning (either vents from main system or stand-alone unit), bathroom fittings and fixtures.

- Once completed the electrics are checked and the plumbing is pressure tested.

- A protective cover is then added for transport and the unit is delivered to site.

- On-site the units are craned into position and joined together.

- The services are connected.

The building is then roofed and clad to the required specification. In some cases, the cladding can be fitted during the module assembly further reducing the on-site work.

Modular building process