FRAMA™ 5600

Dedicated Frames, Trusses, Panels (16 Gauge / 1.6mm)

- Gauge Range

-

- Production Speed

-

- Dimensions L x W x H

-

If you are looking for a system to manufacture heavier and wider sectioned frame and trusses with ease, this machine is ideal. It forms material of up to 1.6mm/16 gauge in thickness.

Producing up to 800m/2620ft of framing per hour, it is designed for a gauge range of 0.95 to 1.55mm/20 to 16 gauge, making it ideal for many residential and commercial applications.

Like the FRAMA™ 3200, the machine features Howick’s unique end-bearing stud detail for load bearing frames. It also has the option of up to 2 additional custom tools for increased flexibility.

| FRAMA™ 5600 | ||

| Dimensions L X W X H | 3.4m x 0.75m x 1.4m | 11.2' x 2.5' x 4.6' |

| Weight | 2400kg | 5291lb |

| Drive Motor Power | 7.5kW | 10hp |

| Hydraulic Power | 5.5kW | 7.5hp |

| Hydraulic Tank | 60L | 15.8gal |

| Forming Stages | 9 | |

| Line Speed | 25m/min | 82'/min |

| Production Speed | up to 800m/hr* | up to 2620'/hr* |

| Touch Screen | Panel PC (Windows 10) | |

| Machine Control | FRAMA Machine Control | |

| Machine Input Files | CSV | |

| Tooling | 9 Standard Tools | |

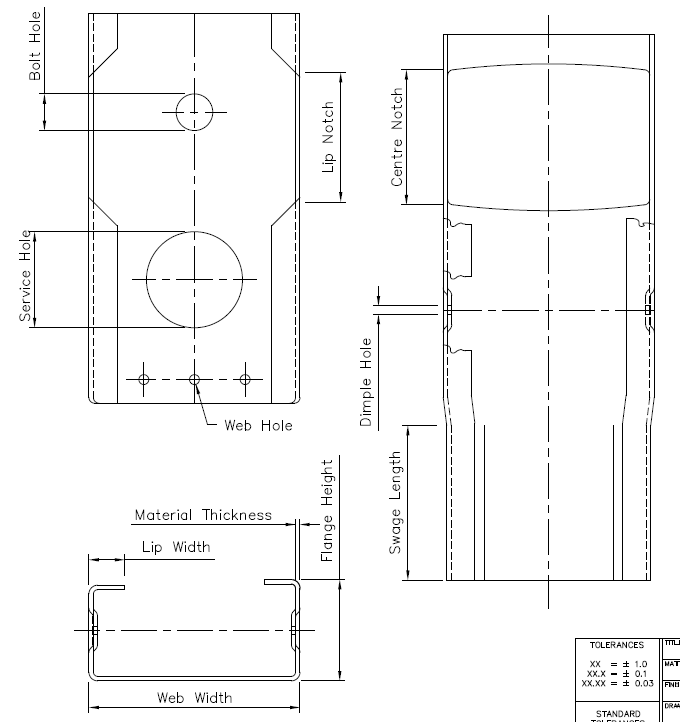

| Provision for 2 additional tools. Truss End Tool, Service Hole, Web Hole, Bolt Hole, Lip Notch, Web Notch, Lip Roller, Dimple, Swage, End Bearing Cut-off | ||

| Component Marking | Dual Head Inkjet Printer | |

| Decoiler | ||

| 3.0T Decoiler | 6600lb Decoiler | |

| Dimensions L X W X H | 1.35m x 1.0m x 1.45m | 4.4' x 3.3' x 4.7' |

| Weight | 700kg | 1550lb |

| Drive Motor | 4.0kW | 5.4hp |

| Jaws | 3 Jaw Self Centring | |

| Jaw Expansion | Hydraulic | |

| Jaw Expansion Range | 480mm - 520mm | 1' 7'' - 1' 8 1/2'' |

| Speed Control | Dancer Arm with Inclinometer | |

| Auto Pause at Coil End | ||

| Max Coil Weight | 3000kg | 6600lb |

| Mac Coil Width | 400mm | 1'3 3/4'' |

| Mac Coil OD | 1500mm | 4' 11"' |

| Nominal Bore | 508mm | 1' 8'' |

| Safety | CE, UL, Cat 3 Compliant | |

| Guarding | Fully Guarded Chains & Electrical Controls | |

| *Production Speed will vary due to component complexity. Howick Ltd Reserve the right to update the machine specification without notice. | ||

STANDARD METRIC SIZES

|

Section Size |

75mm | 89mm | 92mm | 100mm | 150mm |

| Web Width | 75mm | 89mm | 92mm | 100mm | 150mm |

| Flange Height | 45mm | 45mm | 45mm | 45mm | 45mm |

| Lip Width | 10mm | 10mm | 10mm | 10mm | 10mm |

| Service Hole *1 | 34.1mm | 34.1mm | 34.1mm | 34.1mm | 34.1mm |

| Bolt Hole *2 | 13mm | 13mm | 13mm | 13mm | 13mm |

| Web Hole *3 | 3.5mm | 3.5mm | 3.5mm | 3.5mm | 3.5mm |

| Dimple Hole *4 | 3.5mm | 3.5mm | 3.5mm | 3.5mm | 3.5mm |

| Nominal Strip Width | 173mm | 187mm | 190mm | 198mm | 248mm |

| Max Material Thickness | 1.55mm | 1.55mm | 1.55mm | 1.55mm | 1.55mm |

STANDARD IMPERIAL SIZES

|

Section Size |

3'' | 3 1/2'' | 3 5/8'' | 4'' | 5 1/2'' | 6'' |

| Web Width | 3' | 3 1/2'' | 3 5/8'' | 4" | 5 1/2'' | 6'' |

| Flange Height | 1 5/8" | 1 5/8'' | 1 5/8'' | 1 5/8'' | 1 5/8'' | 1 3/4'' |

| Lip Width | 1/2" | 1/2'' | 1/2'' | 1/2'' | 1/2'' | 1/2'' |

| Service Hole *1 | 1 11/32'' | 1 11/32'' | 1 11/32'' | 1 11/32'' | 1 11/32'' | 1 11/32'' |

| Bolt Hole *2 | 1/2'' | 1/2'' | 1/2'' | 1/2'' | 1/2'' | 1/2'' |

| Web Hole *3 | 1/8'' | 1/8'' | 1/8'' | 1/8'' | 1/8'' | 1/8'' |

| Dimple Hole *4 | 1/8'' | 1/8'' | 1/8'' | 1/8'' | 1/8'' | 1/8'' |

| Nominal Strip Width | 6 3/4'' | 7 1/4'' | 7 3/8'' | 7 3/4'' | 9 1/2'' | 10'' |

| Max Material Thickness | 16 Gauge | 16 Gauge | 16 Gauge | 16 Gauge | 16 Gauge | 16 Gauge |