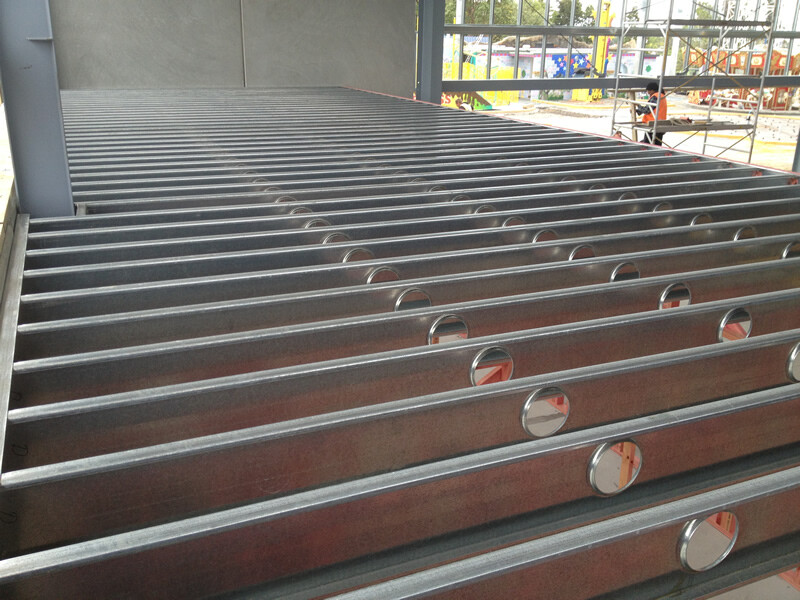

Mezzanine Floors

Howick’s floor joist system is the ideal solution for mezzanine flooring for new and existing buildings.

Floors can either be installed in-situ in existing buildings or as cassettes.

Floor joist system – construction manual

- Fix the perimeter channels in position, align and connect to the supporting structure as per the engineer’s details.

- To install the first joist, fold out the first set of fixing tabs on the perimeter channel. Slide the floor joist into position before folding out the next set of tabs and repeat for each following floor joists.

- Fit the remaining floor joist in position and connect to the fixing tabs with 10 gauge self-tapping screws working from one end to the other. The steel joist at the starting (datum) end should have the open side of the web section facing out. Ensure all joists face the same direction with the boundary joist solid web face to the outside of the building structure.

- Fitting solid blocking. Ensure the joists are parallel and plumb before fixing any required blocking, flooring or ceiling batten. Solid blocking is to be used where required for floor sheet joins or as per an engineer’s specification.

- Once all the previous steps have been completed, the selected flooring can be installed. Speedfloor steel joists suit the use of high density wood panel flooring, plywood, fibre-cement tile and slate underlay flooring which is glued and screwed to the manufacturer’s specifications. 10 or 12 gauge self-tapping or wing tek screws are used to fix the sub floor sheets to the steel joist.

Please note if using plywood with copper based treatments, a barrier of damp proof course must be placed between the joist and plywood materials.

Floor joist system – construction manual

Typical live load span tables – floor joist

| Floor Joists | |||||||

| Profile | Web | Flange | Lip | Material | 400 Centres | 450 Centres | 600 Centres |

| FJ140 | 140 | 45 | 15 | 1.55 | 3.9 | 3.8 | 3.5 |

| FJ190 | 190 | 45 | 15 | 1.55 | 4.7 | 4.5 | 4.2 |

| FJ240 | 240 | 45 | 15 | 1.85 | 5.7 | 5.5 | 5.1 |

| FJ290 | 290 | 45 | 15 | 2.50 | 6.9 | 6.7 | 6.2 |

| *Maximum span (m) of joists at Nominated Spacing (mm) for 1.5kPa floor live load typical for residential applications. | |||||||

| FJ140 | 140 | 45 | 15 | 1.55 | 3.5 | 3.4 | 3.1 |

| FJ190 | 190 | 45 | 15 | 1.55 | 4.3 | 4.0 | 3.5 |

| FJ240 | 240 | 45 | 15 | 1.85 | 5.1 | 5.0 | 4.4 |

| FJ290 | 290 | 45 | 15 | 2.50 | 6.2 | 6.0 | 5.6 |

| **Maximum span (m) of joists at Nominated Spacing (mm) for 3kPa floor live load typical for commercial applications. | |||||||

| FJ140 | 140 | 45 | 15 | 1.55 | 3.0 | 2.8 | 2.4 |

| FJ190 | 190 | 45 | 15 | 1.55 | 3.4 | 3.2 | 2.8 |

| FJ240 | 240 | 45 | 15 | 1.85 | 4.3 | 4.1 | 3.5 |

| FJ290 | 290 | 45 | 15 | 2.50 | 5.6 | 5.3 | 4.6 |

| **Maximum span (m) of joists at Nominated Spacing (mm) for 5kPa floor live load typical for industrial applications. | |||||||

|

*Note: This complies with the relevant provisions of the following Building Codes AS/NZS 1170.0 Structural Design Actions Part 0: General Principles AS/NZS 1170.1 Structural Design Actions Part 1: Permanent, Imposes and Other Actions AS/NZS 1170.2 Structural Design Actions Part 2: Wind Actions AS/NZS 1170.4 Structural Design Actions Part 4: Earthquake Loads AS4600: Cold Formed Steel Structures |

|||||||