Company History

Innovator since day one

Howick began in 1978, when Keith and Bruce Coubray set up a small engineering workshop in east Auckland. They were problem solvers, building one-off machines to handle tough jobs that others could not. That "take it on" attitude has never changed. It still drives the business today.

As demand grew, the focus shifted to roll-forming technology for light gauge steel framing. Howick has delivered key breakthroughs in this space:

- true load-bearing joints for multi-level construction

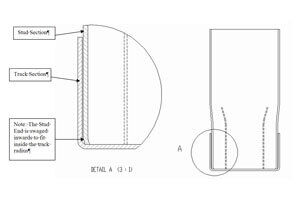

- unique fold-out ‘tab’ connectors and swaged end in steel joist profile for easy and flush connection

- telescopic framing that can be compressed and expanded to fit internal spaces that are never square

- roll-formed structural / portal framing, and more.

These advances have lifted the bar for roll-forming worldwide.

Today, Bruce’s sons Nick and Hamish Coubray lead the company with the same clear focus: build precise, reliable machines in New Zealand, keep R&D close to the factory floor, and learn with our customers and partners. Through real projects, long-term support and events like STEEL HORIZONS, Howick plays an active role in shaping the growth of modern steel construction.

2024

TAMPA 2024 cements STEEL HORIZONS as an event not to be missed on the global construction calendar.

2021

Howick is recognised by TIN (Technology Investment Network) as one of the top 10 Supreme Scale-Ups, based on revenue growth in the past year.

2020

Howick launches its best and most forward-thinking product yet, the X-TENDA 3600™, which promises to transform interior framing

2019

Howick wins ExportNZ Best Medium Business Award, recognising Howick’s role in the automation and future of the global building industry.

2017

Installed 200kN universal testing machine to increase R&D capabilities and product testing

2016

Installed new CNC manufacturing equipment to meet production and R&D growth

2015

First Howick framing on-site manufacture trailer

2015

Introduction of the FRAMA machine Convertible Series

2013

Introduction of the FRAMA range of framing machines

2012

Howick secures Speedfloor partnership with major Indian manufacturer

2012

Howick holds second International Innovation Conference

2011

Howick receives Westpac Award for Excellence in Exporting

2011

Howick recognised by TIN100 as one of NZ’s Top 10 Hot Emerging Companies

2011

Howick receives NZ Metal Industry Innovation Award

2010

Howick holds first International Innovation Conference

2009

Howick designs and builds H400 truss machine

2008

Designed and built H600 floor joist machine

2007

Howick opens sales and support office in the United Kingdom

2006

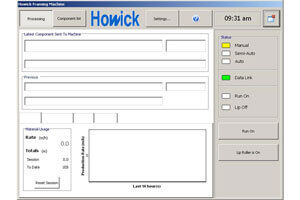

Introduction of Windows based open language controller (CSV)

2004

First mobile factory operates in Hawaii

2003

Developed end-bearing detail that opened the opportunity for high rise LGSF buildings

2003

Developed innovative window well corrugator for Canada that formed and processed the final product

2003

Howick opens new research and development facility for rollfoming services

2002

Launched second generation H500 model steel framing machine

2000

Launched second generation H300 model steel framing machine

1999

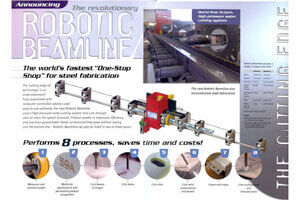

Designed and built Waterjet Beamline

1998

Designed and built first Speedfloor machine

1997

Designed and built compact steel framing machine

1996

Designed and built dual raft steel framing machine

1995

Developed automated garage door production line allowing for custom door size manufacture

1994

Designed and built 30 seater bike for FADE

1993

Built a 12 stand custom multi-section Rollformer 1993

1987

Produced a refrigeration tube bender machine for Fisher & Paykel

1986

Extended Howick factory

1978

Keith and Bruce Coubray start Howick Engineering