KMPL - Mistletoe Avenue Social Housing Project

Kununurra, Western Australia

Building housing to withstand the harsh environment of northern Western Australia can be a massive challenge.

That is why Kullarri Building engaged Kimberley Manufacturing Pty Ltd (KMPL) before beginning a social housing project in the area. KMPL is a well-established local manufacturer and supplier of light gauge steel (LGS) with the experience, and the robust, resilient product necessary.

Thanks to KMPL’s local capabilities and their use of Howick’s precision steel roll-forming technology, Kullari Building was able to deliver quality, resilient homes to those most in need - on time and on budget.

The project: Kununurra social housing

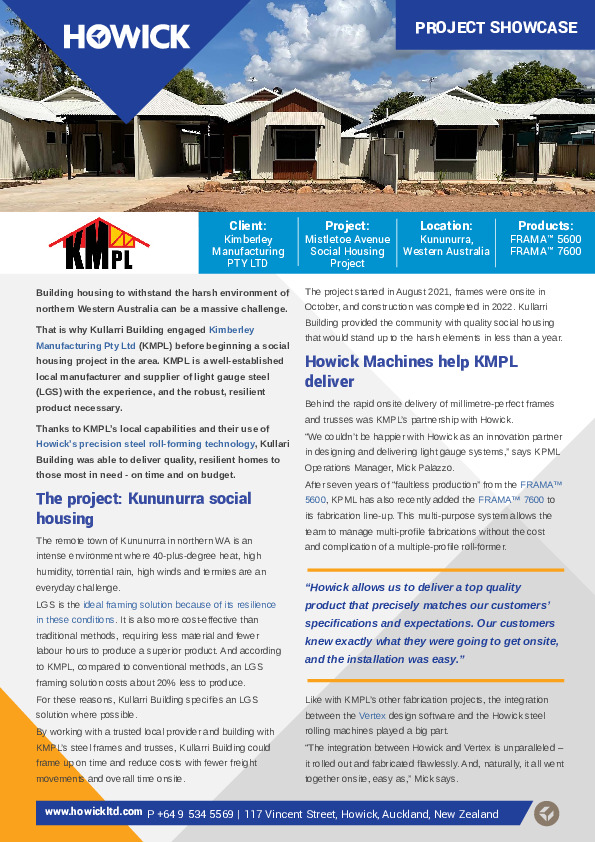

The remote town of Kununurra in northern WA is an intense environment where 40-plus-degree heat, high humidity, torrential rain, high winds and termites are an everyday challenge.

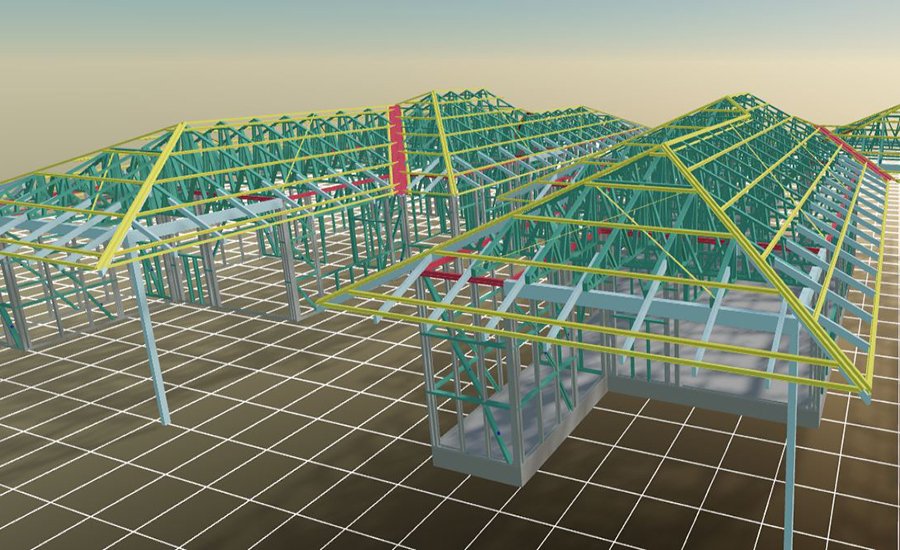

LGS is the ideal framing solution because of its resilience in these conditions. It is also more cost-effective than traditional methods, requiring less material and fewer labour hours to produce a superior product. And according to KMPL, compared to conventional methods, an LGS framing solution costs about 20% less to produce.

For these reasons, Kullarri Building specifies an LGS solution where possible.

By working with a trusted local provider and building with KMPL’s steel frames and trusses, Kullarri Building could frame up on time and reduce costs with fewer freight movements and overall time onsite.

The project started in August 2021, frames were onsite in October, and construction was completed in 2022. Kullarri Building provided the community with quality social housing that would stand up to the harsh elements in less than a year.

Howick Machines help KMPL deliver

Behind the rapid onsite delivery of millimetre-perfect frames and trusses was KMPL’s partnership with Howick.

“We couldn’t be happier with Howick as an innovation partner in designing and delivering light gauge systems,” says KPML Operations Manager, Mick Palazzo.

After seven years of “faultless production” from the FRAMA™ 5600, KPML has also recently added the FRAMA™ 7600 to its fabrication line-up. This multi-purpose system allows the team to manage multi-profile fabrications without the cost and complication of a multiple-profile roll-former.

Like with KMPL’s other fabrication projects, the integration between the Vertex design software and the Howick steel rolling machines played a big part.

“The integration between Howick and Vertex is unparalleled – it rolled out and fabricated flawlessly. And, naturally, it all went together onsite, easy as,” Mick says.

Building communities one home at a time

KMPL has provided residential, commercial and industrial construction operations with quality steel fabrications for 25 years. They are renowned for providing a one-stop-shop solution for detailing, certification, frames, trusses, structural and all associated fixings.

Proudly indigenous owned, KMPL has won multiple awards and is the only roll-forming company north of Perth to have achieved CC2 (quality compliance) accreditation through Steelwork Compliance Australia (SCA).

SCA is the certifying body for the National Structural Steelwork Compliance Scheme (NSSCS) and provides a tough and rigorous steelwork technical prequalification scheme. To qualify for the Australian steel work standard AS/NZS 5131 certification, fabricators like KPML must meet their demanding standards for practices, systems, personnel and training.

KMPL, which operates in Broome in the Kimberley region of the northern reaches of Western Australia, says they felt “particularly lucky” to help contribute to much needed social housing programmes across the region and is full of praise for Kullarri Building.

Kullarri Building – another indigenous owned company – is renowned for delivering a quality product and “building up the community through employment and investment.”

With a chronic shortage of affordable housing and social housing in the Kimberly area, the local community celebrates new homes like those delivered by Kullarri Building.

Benefits delivered:

- Reliable supply chain during timber crisis

- Houses framed in 1-2 days

- Reduced waste onsite