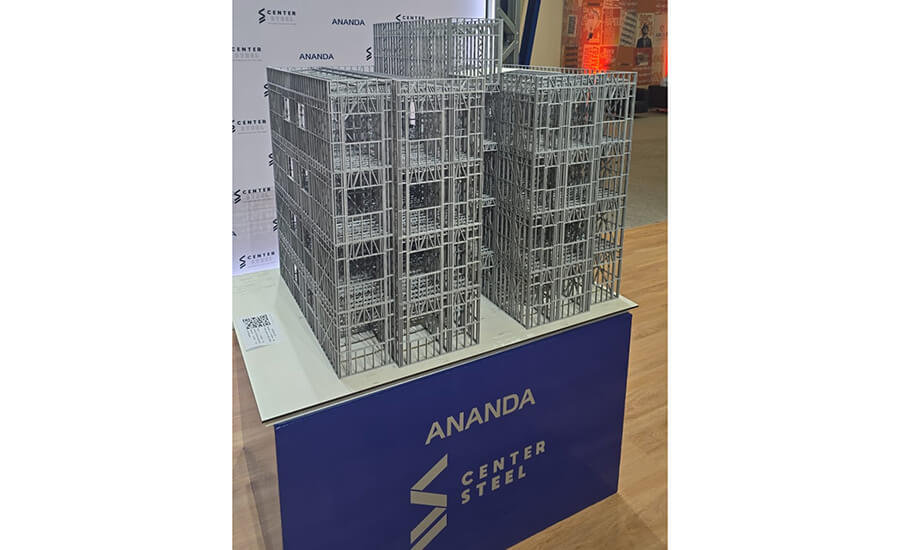

CenterSteel - Worker Accommodation, Inocência, Brazil

Inocência, Brazil

High-speed delivery for industrial-scale accommodation

Company: CenterSteel Engenharia Ltda.

Client: Metril Construtora Ltda.

Location: Inocência, Mato Grosso do Sul, Brazil

Project Type: Worker Accommodation – 15 Buildings, 240 Apartments

Total Floor Area: 12,300m²

Completion Time: 3 months

Howick Technology Used: FRAMATM 3200, 100mm profiles

Design Software: Vertex BD

Fast-tracking accommodation for 14,000 workers for Brazilian mega-project

When Metril Construtora needed to rapidly house workers for what would become the largest cellulose manufacturing plant in the world, speed, scale and precision were critical.

In response, CenterSteel Engenharia was engaged to deliver a fast track solution using light gauge steel framing. The result was a full scale accommodation village built in an impressive timeframe: 15 buildings, 240 fully completed apartments, all delivered in just three months.

Each unit measured 47m², with the team completing an average of 2.81 apartments per day. This level of output was only possible with offsite manufacturing, digital design and the precision of Howick roll-forming technology.

Achieving scale with Howick technology

At the core of the construction process was CenterSteel’s Howick FRAMATM 3200, producing 100mm framing with high precision and consistency.

This enabled the production of wall, floor and roof frames to exact specifications, streamlining onsite assembly and eliminating costly delays.

Digital design driving efficiency

CenterSteel used Vertex BD for all project modelling and manufacturing output. With over 15 years of experience working with the platform, their engineering team fully leveraged its capabilities to ensure seamless integration with their Howick machinery.

From concept to construction, the digital-to-physical workflow allowed for faster coordination, reduced manual rework, and ensured accuracy at every stage of production.

Key benefits delivered

The use of light gauge steel and Howick technology delivered a range of benefits:

- Ultra fast build timeline with 240 apartments in just 90 days

- Labour and cost savings via offsite manufacturing

- Minimal material waste through precision roll-forming

- High dimensional accuracy for faster installations

- Enhanced thermal and acoustic performance

- On time, on budget delivery with next to zero scope creep

Despite the project scale and tight deadlines, the entire development was delivered without compromise on quality or performance.

About CenterSteel Engenharia

Founded in 2011, CenterSteel Engenharia (Engineering) Ltda. is on a mission to modernise construction with more efficient and economical solutions.

They are a team of engineers who specialise in solving longstanding problems in the building industry using smart design and advanced light steel framing systems. With over 2,600 completed works and more than 367,000m² of structures delivered, they are setting new benchmarks for speed, quality and sustainability in Brazil’s mid-rise construction sector.

Their approach combines conscience, competence, and technology, and brings together the best people, tools and processes to simplify site management and eliminate waste.

Learn more at: centersteel.com.br

If this was useful, please share it with your network!