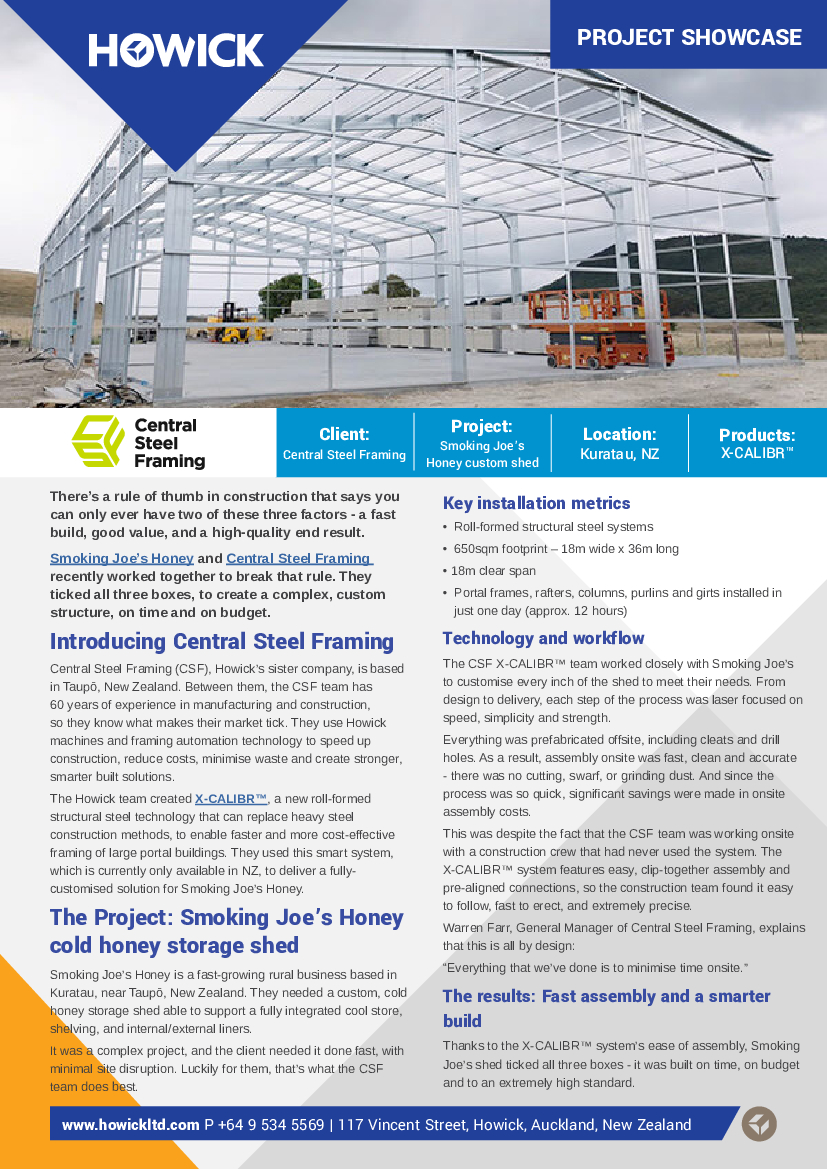

Central Steel Framing - Smoking Joe’s Honey 650sqm (6997sqft) shed installed in one day

Kuratau, New Zealand

There’s a rule of thumb in construction that says you can only ever have two of these three factors - a fast build, good value, and a high-quality end result.

Smoking Joe’s Honey and Central Steel Framing recently worked together to break that rule. They ticked all three boxes, to create a complex, custom structure, on time and on budget.

Introducing Central Steel Framing

Central Steel Framing (CSF), Howick’s sister company, is based in Taupō, New Zealand. Between them, the CSF team has 60 years of experience in manufacturing and construction, so they know what makes their market tick. They use Howick machines and framing automation technology to speed up construction, reduce costs, minimise waste and create stronger, smarter built solutions.

The Howick team created X-CALIBR™, a new roll-formed structural steel technology that can replace heavy steel construction methods, to enable faster and more cost-effective framing of large portal buildings. They used this smart system, which is currently only available in NZ, to deliver a fully-customised solution for Smoking Joe’s Honey.

The Project: Smoking Joe’s Honey cold honey storage shed

Smoking Joe’s Honey is a fast-growing rural business based in Kuratau, near Taupō, New Zealand. They needed a custom, cold honey storage shed able to support a fully integrated cool store, shelving, and internal/external liners.

It was a complex project, and the client needed it done fast, with minimal site disruption. Luckily for them, that’s what the CSF team does best.

Key installation metrics

- Roll-formed structural steel systems

- 650sqm (6997sqft) footprint – 18m (59ft) wide x 36m (118ft) long

- 18m (59ft) clear span

- Portal frames, rafters, columns, purlins and girts installed in just one day (approx. 12 hours)

Technology and workflow

The CSF X-CALIBR™ team worked closely with Smoking Joe’s to customise every inch of the shed to meet their needs. From design to delivery, each step of the process was laser focused on speed, simplicity and strength.

Everything was prefabricated offsite, including cleats and drill holes. As a result, assembly onsite was fast, clean and accurate - there was no cutting, swarf, or grinding dust. And since the process was so quick, significant savings were made in onsite assembly costs.

This was despite the fact that the CSF team was working onsite with a construction crew that had never used the system. The X-CALIBR™ system features easy, clip-together assembly and pre-aligned connections, so the construction team found it easy to follow, fast to erect, and extremely precise.

Warren Farr, General Manager of Central Steel Framing, explains that this is all by design:

“Everything that we’ve done is to minimise time onsite.”

The results: Fast assembly and a smarter build

Thanks to the X-CALIBR™ system’s ease of assembly, Smoking Joe’s shed ticked all three boxes - it was built on time, on budget and to an extremely high standard.

Wallace Steel, owner of Smoking Joe’s, was buzzing when the build finished:

“X-CALIBR™ was willing to customise it to our needs, which was going to save us quite a lot in assembly costs. I’m amazed at how fast it went up actually.”

The end result was a durable, high-performance structure that was tailored to the needs of a fast-growing rural business (and completed within a tight timeframe, with less waste).

You built that already?

When the build was nearly finished Warren says there was very visible evidence of how good the X-CALIBR™ system really is:

“Next door there was a similar shed that was started on Jan 20th and on March 12th it wasn’t even close to being ready for cladding. Ours started on Feb 20th and by March 12th the building was nearing completion, including installation of a large cool store.”

“My favourite bit about visiting the site was hearing the builders say none of their shed building mates could believe that they didn’t have to cut or drill anything, and that it was done so fast.”

Benefits Delivered

- Very strong, lightweight construction with strength matching that of hot-rolled steel construction but without the downsides

- Custom build delivered, without a custom price

- A high level of precision in all structures thanks to Howick technology. Simplicity of assembly thanks to CSF’s smart design and X-CALIBR™ technology

- Zero waste onsite

- Extremely fast build times, and minimal disruption to site

- Minimal labour required for assembly delivered significant cost savings

About X-CALIBR™

X-CALIBR™ is a New Zealand-made roll-formed structural steel framing system developed by Howick. It offers a smarter, faster alternative to traditional steel portal framing - perfect for sheds, workshops, packhouses, and more.

Every project is custom-designed and manufactured offsite using Howick roll-forming machinery, reducing material waste and maximising build efficiency.

X-CALIBR™ is currently available exclusively in New Zealand, only from Central Steel Framing.

Want to find out more about X-CALIBR™? Visit centralsteelframing.co.nz

If you found this article valuable, don’t forget to share it!