Dave Cooper interviews Jaimie Johnston MBE from Bryden Wood

Digital to Physical Buildings and Kit of Parts Construction P-DfMA

“The Future of Construction” series is part of Howick’s STEEL HORIZONS thought leadership initiative. It is our commitment to championing better ways to build and inspire the construction sector. Hosted by renowned construction industry online talk show host Dave Cooper, this series explores the world of high-tech advanced methods using real-world case studies.

In episodes 1-3, Dave Cooper discusses offsite manufacturing with the team at British Offsite.

In episodes 4-6, Dave Cooper explores digital-to-physical design with the team from Bryden Wood – a leader in the theory and practice of Modern Methods of Construction (MMC), the Platform approach to Design for Manufacture and Assembly (P-DfMA), generative design, creative technologies, integrated design and automation in construction.

After looking at design automation with Phil Langley, Head of Creative Technologies, in episode 4, in this episode 5, Dave sits down with Jaimie Johnston, MBE, Head of Global Systems. Together they discuss how data will impact the future of the construction industry, and how the team at Bryden Wood are using digital-to-physical workflows to deliver projects of previously unimaginable complexity.

How technology is transforming construction

Digital technology and digital-to-physical workflows are changing more than just how we build. They are starting to transform the DNA of the construction industry, says Jaimie.

“I think the industry thinks there is a digital thing happening, and there is an industrialised construction thing. In our minds, the two strands are the same.”

While others simply add technology to the traditional design, procurement, and building process, Bryden Wood has taken a more blue-sky approach.

“What we do is say, “If you had this technology, what would you do with it?” Because you wouldn't reinvent the normal way of designing and building things,

“What would be the way you'd change your whole design process? What's the next piece of capability that we need to get right?”

This approach has allowed the company to explore new possibilities and find ways to use technology to create a better value offering for clients.

Getting hard data to do the hard work

With its design-for-value philosophy and focus on digital-to-physical workflows, Bryden Wood has grown to include a diverse range of talent, including creative technologists, coders, designers, engineers, robotics experts, data analysts and more.

As a team, they are helping clients around the world realise the potential of digital technology and data to test and cost virtual prototypes and automate labour-intensive tasks.

"We're seeing lots of clients have tons of data, but they don't necessarily know what to do with it," says Jaimie.

“So part of our job is taking data that clients have got and working out how to generate information, insight, and something off the back of it.”

Dave Cooper agrees this move to embrace data will prove a critical factor for the future of construction.

“Stakeholders in the industry who are looking to build products are starting to understand the value of the data they have, or the data they could get, to speed up their projects and time to market,” says Dave.

Platform Kit of Parts forging real change

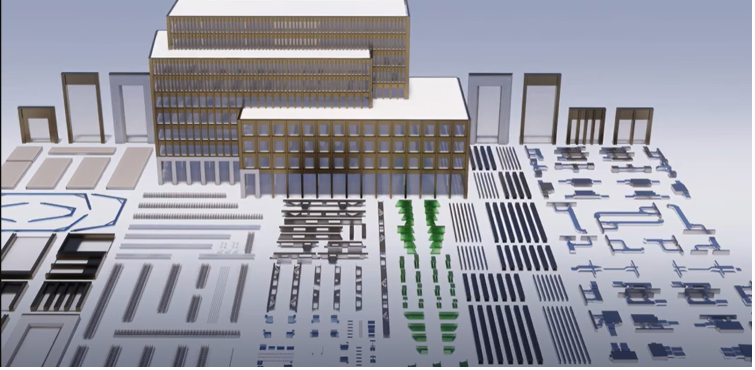

The Forge is a new office building in central London and the first commercial building constructed using Bryden Wood’s new Platform Kit of Parts model.

A Kit of Parts is a system of separate proprietary parts manufactured off site, intended to be efficiently assembled onsite.

Image courtesy of Bryden Wood.

Jaimie describes yet another way they are using technology and data to change the face of the construction industry:

“You’ll see how closely integrated the superstructure and the MEP are. We got incredible bursts of productivity because of the pre-kitting of everything and the accuracy of the components.”

“Once the superstructure was up, the façade came as a Kit of Parts. They were able to install the façade panels in 7 ½ minutes, which is lightning-fast. And the MEP was all pre-kitted and delivered up to the slab, so the productivity in those two packages was incredibly good.”

“Theoretically, you could have built that building in half the time, but logistics is the next big thing we need to get into now.”

A global view on the use of data and digital-to-physical workflows.

As a global company with an established footprint in the UK and now a growing presence in the US market, Bryden Wood sees the general similarities and differences.

“The problem statements are the same all around the world. It is about productivity, carbon sustainability, labour shortage and those things.”

However, where the drive for change is coming from government in the UK, in the US, it is being driven by the supply-side through large-scale clients and manufacturers.

“The clients are pushing it from the top. The manufacturers are coming up the value chain. So, we're starting to see these things link up, and that's going to be the thing that transforms it.”

More about STEEL HORIZONS

STEEL HORIZONS is a thought-leadership initiative launched by Howick Ltd. As a pioneer and world leader in light gauge steel, we are passionate about the possibilities of technology, automation and data; and about bringing together the brightest minds in the offsite and modular industry to collaborate and inspire each other.

If you are interested in accessing videos and presentations from our 2022 UK event, simply click here and join us.

Click here to see this interview with Jaimie Johnston, MBE, from Bryden Wood