STEEL HORIZONS | TAMPA: Simple/Complex with Scott Mitchell

⏱️ 6 min read

Ever wonder how industry leaders are tackling construction's toughest challenges and building smarter for the future? Then you've come to the right place.

Welcome to the STEEL HORIZONS Speaker Spotlight, where we unpack the most insightful moments from the recent STEEL HORIZONS | TAMPA event, so you can stay up to speed with the latest perspectives and technologies shaping the world of construction.

In this spotlight, Scott Mitchell, the Founder and CEO of STUD-IO, explores the idea of simple and complex projects and how focusing on repeatable processes, not one-off solutions, has driven their success, and delivered game changing results for clients.

Focusing on processes, not projects

“Maybe it doesn’t make sense to call projects simple because inherently construction is just complex. Instead, I think it makes more sense to think about simple and complex processes.”

Returning for his third STEEL HORIZONS, the evolution of Scott Mitchell’s presentations offers a unique insight into how fast our industry is transforming— and how fast ideas can shift.

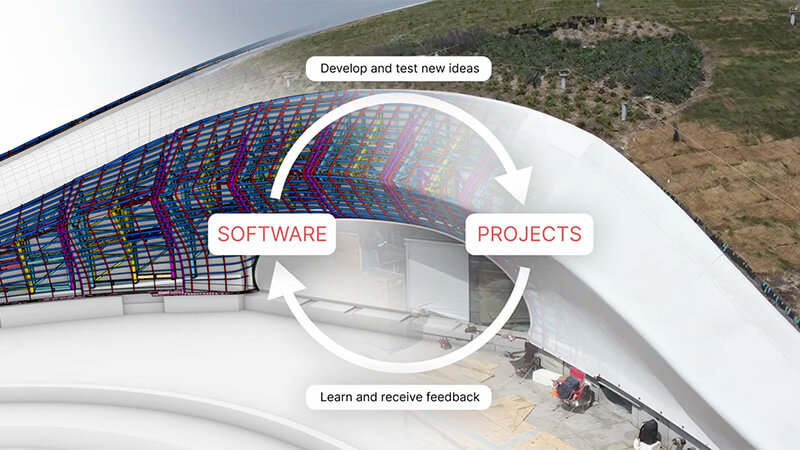

In London, the central theme was experimentation, and how you can create complex geometries using a Howick machine. In Boston, he showcased the ways STUD-IO was applying complex, automated fabrication to large-scale commercial projects. Now at TAMPA, the focus has evolved again, to leveraging the learnings and process principles behind complex projects and using them to accelerate more standard projects, delivering next-level efficiency.

Behind this rapid advancement is a core belief: Whether a project is complex or simple is the same – concentrate on developing repeatable processes, not one-off solutions.

“I think this focus on process over projects is the engine that has propelled STUD-IO.”

Lucas Museum: A masterclass in managing complexity

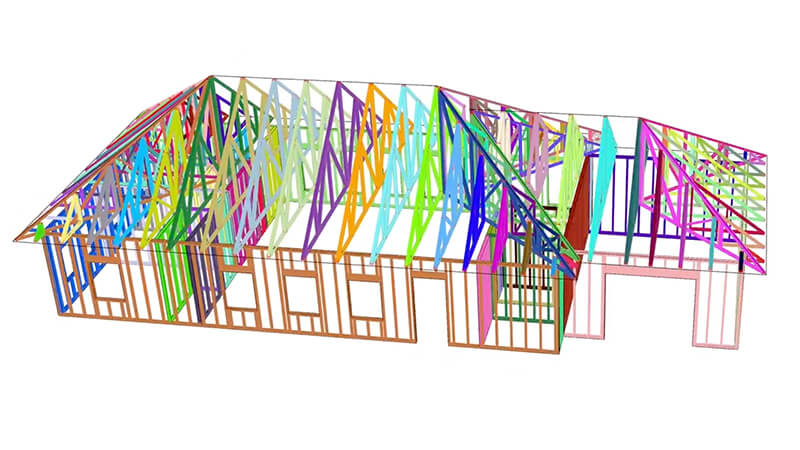

From the start, complex projects have been the bread-and-butter of STUD-IO. Projects like the Lucas Museum in LA, which Scott first introduced us to in London 2022.

Now a year away from opening, STUD-IO’s solution for its mind-bending roof ribbon is a masterclass in computational construction.

STUD-IO used their own software to break the ribbon into 195 unique panels, each with complex geometry. Each panel began with a primary frame, roll-formed by Howick machines with precisely punched holes. These holes allowed secondary frames to be added and aligned perfectly, creating the curved shape needed.

The Howick-manufactured frames then acted as a jig, guiding the placement of primary and secondary ribs. Together, they formed a structure that followed the architect’s 3D model with high precision.

Onsite, digitally fabricated rails were installed in advance, and robotic layout was used to place each panel exactly where it needed to go.

This repeatable system allowed complex forms to be built quickly and accurately—one of the main reasons the ribbon was finished six months ahead of schedule.

“When we work on a project, we don't work on the project. We work on a process that's going to work on the project for us.”

The real gold for STUD-IO isn't in nailing one-off challenges. It’s in extracting the process principles that can consistently and efficiently handle complexity, project after project. Over time, those hard-won, seemingly custom solutions evolved into adaptable, and – crucially – scalable systems.

“The increase in our efficiency from design to fabrication, from the first to this most recent scope, is kind of crazy. And it’s because we think incessantly about process.”

Shifting from bespoke to everyday efficiency

After years of perfecting processes for bespoke, high-profile builds, STUD-IO is now mastering a new challenge:

How do you bring that same efficiency to everyday projects?

While custom projects taught them how to manage extreme complexity, most construction projects demand something different: speed, flexibility, and scalability.

“We want to help propel the entire industry forward. So we've very intentionally been developing software and working on projects for simple construction.”

This shift in focus has led to what may be a tipping point event for the industry: The creation of Regions and Recipes. This is a powerful frame-generating tool that applies the principles of process automation to standard panel construction.

Regions and Recipes: Codifying expertise, not just automation

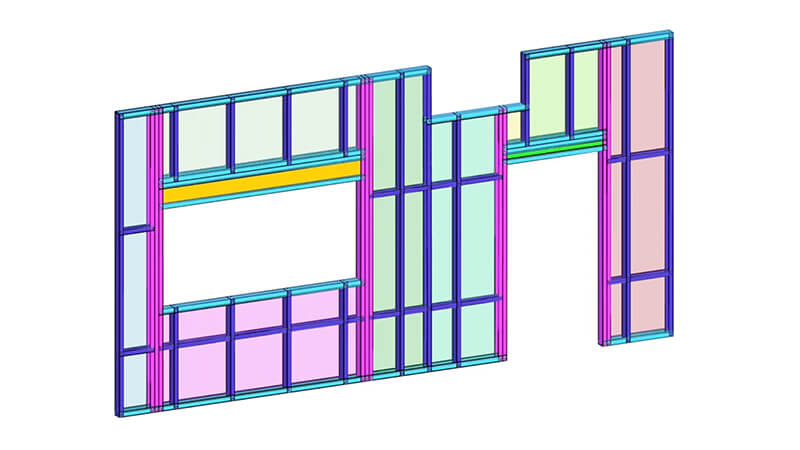

Regions and Recipes is a powerful frame-generating tool built on a simple but powerful idea:

Give the system a shape, and it figures out the rest.

You define a recipe—a set of instructions that tells the system where to place studs, how to frame around openings, and what details to apply. Then, no matter the panel size or shape, the system automatically generates the fabrication information.

- Define once, apply everywhere. Recipes become adaptable templates that effortlessly adjust to different shapes and sizes, instantly eliminating hours of tedious manual work.

- Embrace design changes. If the project evolves the system dynamically updates the framing in real-time, keeping pace with design iterations.

- Retain the human touch. Need to fine-tune a detail? You can jump in and manually tweak the system at any point, blending automation with expert intervention.

By codifying expertise into simple, repeatable steps, Regions and Recipes empower users to manage complexity with confidence. What was once bespoke is now scalable, and what was once manual is now intuitive.

“We want people to think about designing the systems that are going to model their framing for them.”

The future of construction: Powered by simple, scalable processes

As the construction industry becomes increasingly complex – with ambitious designs, tighter timelines, and evolving demands – STUD-IO's process-first philosophy offers a clear path forward.

It's a vision where simple rules produce complex systems that do the hard work, creating confidence and giving back control.

It’s not about shaving minutes off schedules or percentages off budgets. It’s about unlocking the potential of our industry to work smarter, build faster and deliver better outcomes – at scale.

Stay tuned for more insights from STEEL HORIZONS | TAMPA, and if you’re ready to transform the way you build, let’s talk.