SMART BUILD SPOTLIGHT: Wernick builds on tradition to shape a steely future

⏱️ 4 min read

Welcome to another of our SMART BUILD SPOTLIGHT series, where we profile construction trailblazers using cutting edge technologies to raise the bar in our industry.

Our next stop is South Wales, where Wernick Buildings is showing how tradition and innovation can work together.

From building chicken boxes in 1934, Wernick Group has grown to become Britain's largest independent manufacturer and hirer of portable and modular accommodation. Behind this success are two clear traits: a willingness to constantly evolve and embrace new technologies, such as roll-forming and light gauge steel (LGS), and a commitment to its people. Apprentices and new leaders work alongside experienced staff, creating a culture that values both tradition and innovation.

Watch the SMART BUILD SPOTLIGHT interview video OR read the article below to get the full story.

All our SMART BUILD SPOTLIGHT episodes are now available on our YouTube channel. If you haven’t already, subscribe today and immerse yourself in thought provoking content.

No time? Here is a quick summary of the key points:

-

From chicken boxes in 1934 to £250m turnover today, Wernick Group has grown through adaptability and long term vision.

-

People and culture have been central to Wernick's growth and success, and the company invests in developing a resilient and loyal team.

-

Transitioning from timber to light gauge steel has reduced waste, increased efficiency, and improved staff well-being.

-

Choosing Howick machines provides flexibility, reliability, and strong technical support.

-

Apprentices and experienced carpenters work side by side, backed by a supportive four-day work culture.

-

Vision 2030 aims to double turnover by investing in people, skills, and proven technology.

Wernick builds the future

When we stepped onto the shop floor with the team from Wernick Buildings, it was clear that this was a business both proud of its heritage and focused on the future.

Wernick Buildings specialises in designing and delivering modular and portable buildings for clients across the UK, from schools and offices to healthcare and accommodation facilities. And, from the leadership team to the machine operators, everyone had a story to tell about how they were adapting to change.

Originally started by family members who emigrated from Poland at the turn of the last century as butchers, in 1934, the family pivoted to carpentry when they found they made more money from selling chicken boxes than the actual chickens.

From this humble beginning, Wernick Group today operates 35 sites across the UK and turns over £250 million.

As a family-owned business ourselves, Wernick's story resonates with us at Howick. We share the same generational outlook and believe that investing in people, our community, and our technology for the long term is what drives our success.

As Managing Director of Wernick Buildings Ben Wernick explains it:

"The advantage of being a private company is decision-making is very quick. You've got senior leadership that thinks in terms of generations, opposed to satisfying shareholders. So that then filters all the way down that the people, the whole way through the organisation, know that the senior leadership team are not in it for the short term."

Managing Director of Wernick Buildings Ben Wernick

From timber to steel: A turning point

Today, a significant focus of Wernick Buildings is transitioning from timber to light gauge steel (LGS) and roll-forming technology. While timber has its advantages, the drawbacks for a modern modular operation can be considerable.

There is the waste, the combustibility concerns, the storage demands, the weight, the constant dust, and then there is the high rejection rate.

As Wernick Building Production Manager Tom Rhoden explains:

"With the timber, having that natural product come through the lines and susceptible to the damp, the dry, the heat, the cold... they warp, they bend, they split. All sorts of different things were happening with the timber."

Tom Rhoden, Production Manager Wernick Buildings

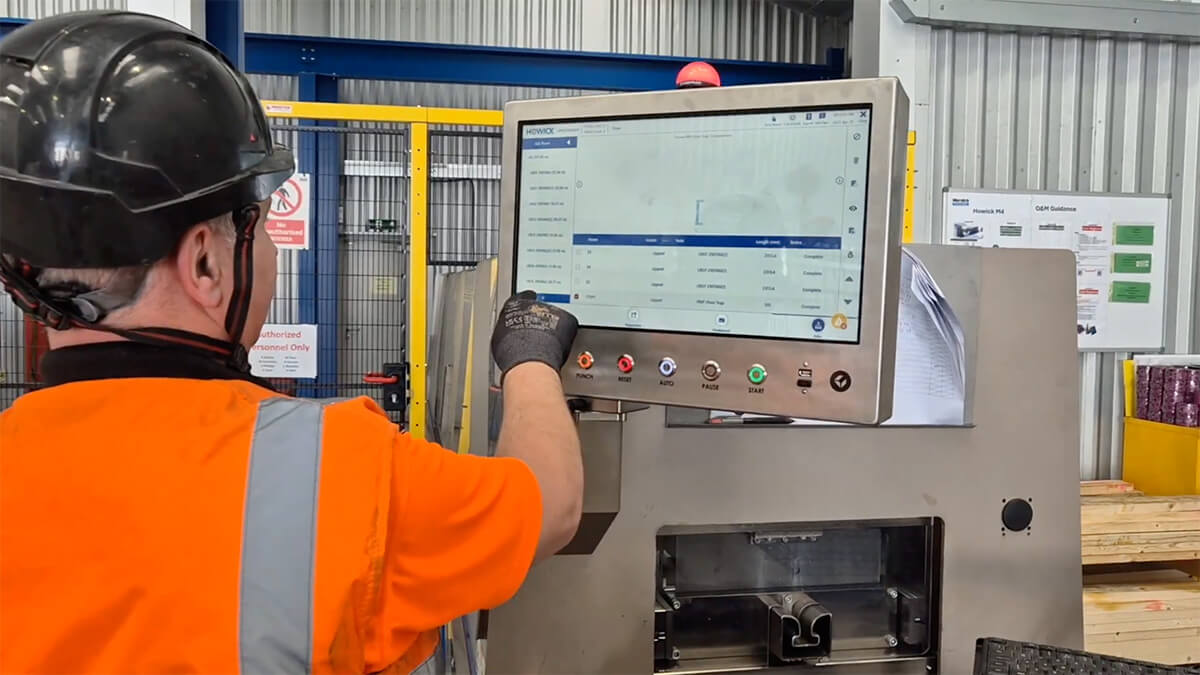

Since introducing a Howick roll-forming machine two years ago, the factory has run a zero rejection rate for steel components. Waste is minimal, offcuts are fully recyclable, and the steel coils take up a fraction of the storage space. While it may be easy to overlook, storage efficiency is critical to a growing company like Wernick, says Tom.

"It's just worlds apart. So we got thousands of linear meters of storage capacity within a really small space. Whereas the equivalent in timber fills a barn outside for us."

For Mark Hamilton, Wernick Buildings' Panel Assembly Team Leader and a lifelong carpenter with 30 years of experience, his initial reservations quickly faded when he and his team started working with the Howick machine, which he now fondly refers to as "my baby":

"When he said you're having a metal machine coming in to push metal panels, [I thought], "Oh here we go!"...[But] Everybody has taken it on board, and they think it's brilliant. So much better for their well-being purely because of the weight of the panels they're now not lugging."

Choosing Howick and switching to steel

Wernick Buildings' transition to LGS had started years earlier when Ben was serving in the British Army in Afghanistan. As an officer in the Royal Engineers, he saw firsthand the speed and efficiency roll-forming technology brought to modular builds. When he returned home, he realised its potential for the Wernick Group.

"Our R&D manager was also very interested in light gauge steel. So we started looking at it and we looked at it for a couple of years altogether."

After comparing roll-forming machine suppliers and visiting other businesses involved in offsite construction, Wernick Buildings decided to invest in the versatile Howick FRAMA™ 7600, which can handle five different profiles and covers a range of construction needs.

As future production ramps up, Ben expects they will add dedicated single-profile machines to match demand.

While Howick's technology did not disappoint, it is the service and trust that set them apart, says Tom.

"A big part of choosing Howick as our choice for the LGS was the fact that the feedback from the technical support was superior to others...which we've seen firsthand. We've had multiple trips down, and they're always on the end of the phone."

Growing generational skills and knowledge

The story of steel at Wernick is also the story of its people. Experienced veteran carpenters, like Mark, stand alongside apprentices as they begin their careers.

"It is all about getting the balance right and nurturing new talent," says Tom.

"We currently have seven apprentices with us onsite. Carpenter apprentices at different stages of their apprenticeships...They can be as young as 16 or 17."

That mix creates resilience: fresh ideas from younger recruits, grounded by the steady hands of seasoned staff. It also keeps the culture dynamic.

For Tom, who studied to be a teacher before starting his own construction business, the move to Wernick Buildings was eye-opening. He was struck by how the company manages to combine corporate scale with a family atmosphere:

"We have such support from the group...If something makes sense, we're encouraged to make that business plan and just run with it."

At every point, the business is prepared to do things differently and keep the focus on the results. Their four-day work week is just another example of this strong work culture in action. Introduced a year ago, the business compressed the same hours into fewer days without cutting pay or productivity. In fact, the factory has seen a slight uplift, and that was not a surprise, says Ben.

"A happy workforce is key to a sustainable business."

The home of Wernick Buildings at Kenfig Industrial Estate in South Wales

Challenging assumptions

While the factory floor demonstrates a pragmatic approach to radical change, Wernick's leadership is also challenging assumptions at every point. Even the phrase "Modern Methods of Construction" isn't safe from Ben's forthright common sense.

"The whole phrase of Modern Methods of Construction is just ridiculous," he told us. "Because the original construction was modular. It was temporary, which would've been tents."

"From a historical military perspective, the first recorded example of a temporary building was actually 1066, the Battle of Hastings, when the French brought over with them modular forts."

"It's just a phrase we should actually drop...We should just call it 'buildings'."

For Wernick Buildings, the debate is not about labels. It is about outcomes. Ben advises clients to be clear from the outset about priorities and the balance between cost, quality, and time.

"Work out what you need and then have a conversation to see if modular is the way forward or feasible. And if it is, speak to a modular provider."

The road ahead: Vision 2030

Looking ahead, Wernick is now preparing for its next chapter. Its "Vision 2030" plan is to double turnover by the end of the decade.

The strategy here is not just about financial growth, but also about building capacity in people, training the next generation, and developing the future skills needed. It is also adopting proven technologies, like Howick's roll-forming machines, and refining processes to increase efficiency and resilience.

Underpinning it all is the same long-term mindset that has sustained the business for nearly a century.

"If you try and just carry on, in the end you'll lose. You've got to continue moving," says Ben.

Building pride into every panel

If we had one word to describe Wernick Buildings, it would be: Pride. From Ben's long-term vision, to Tom's focus on culture, to Mark's embrace of "his baby"; Wernick is a company defined by its people as much as its processes.

The transition from timber to steel is more than a technical shift. It is a cultural one, balancing tradition with innovation, experience with new energy. With Howick technology at its core, Wernick Buildings is building strong and proving that the smartest construction is always about people, culture, and the tools that enable them.

All our SMART BUILD SPOTLIGHT episodes are now available on our YouTube channel.

We travel around the world and meet with industry trailblazers to explore how they are pushing the boundaries with smarter construction methods. Each episode gives you a behind the curtain look into how different businesses combine people, process and technology to achieve outstanding results.

If you haven’t already, subscribe today and immerse yourself in thought provoking content.