STRUCSOFT SOLUTIONS - They built it and the floodgates opened

The phenomenal rise of an AEC software company

George Ajami has been making waves in the world of software programming for a long time.

Canadian-based George Ajami is the founder of StrucSoft Solutions. Way back - shortly after graduating as a structural engineer - he was working long hours in a mining-related industry.He quickly identified that automation was the solution to a hugely repetitive job and suggested he write a programme. Determined, George used a long weekend to develop a relevant software programme and when his superiors saw its capabilities, they were gobsmacked. He sold the programme – that took him two days to devise – for more than a month’s pay.

George Ajami, founder of StrucSoft Solutions

Fast forward many years and this innovative and solutions-driven businessman can say he has been backing the right horse for decades.

“We are riding the wave of automation in construction and you can’t automate without software,” George asserts.

Howick is proud to be, in some way, involved in George’s incredible story and delighted to continue to work in partnership with this inspirational company.

|

|

StrucSoft and Howick collaborating at tradeshows

A snapshot of StrucSoft Solutions

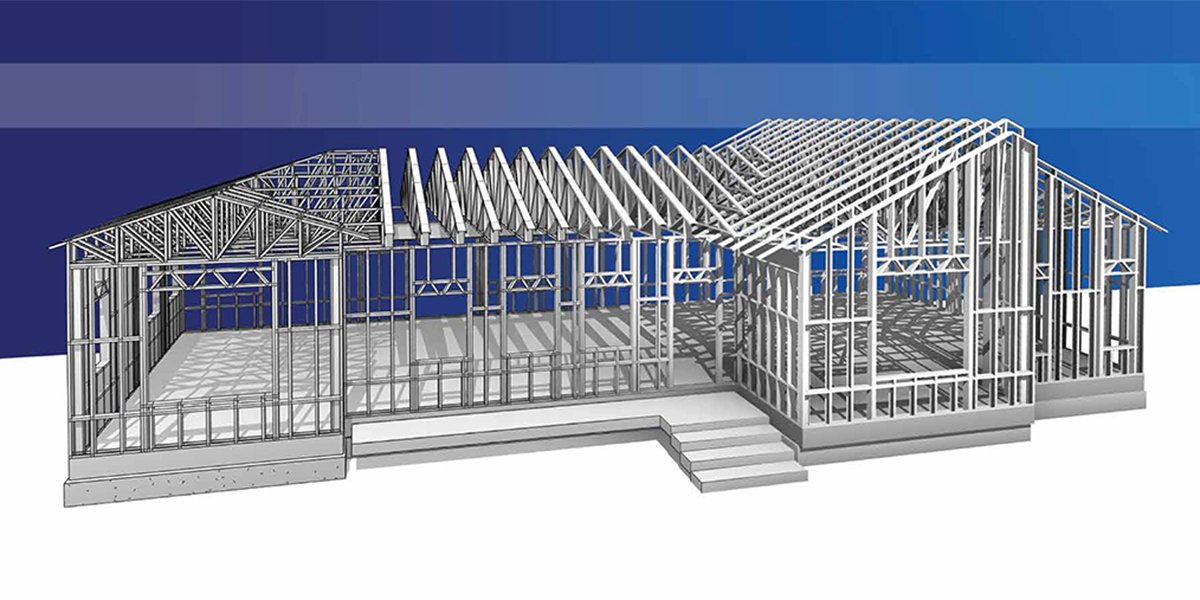

StrucSoft Solutions is a market leader in comprehensive Revit®-based Building Information Modelling (BIM) framing, with a focus on the Architecture, Engineering, Construction (AEC), and fabrication sectors. StrucSoft masterfully leverages BIM technology to digitalise and automate the creation and flow of manufacturing data from design model to shop floor.

The Revit® - based software achieves great things in the world of structural steel, wood and light gauge metal construction – offering both off-the-shelf and customised solutions. Amongst the many solutions developed by this innovative and collaborative company is Metal Wood Framer (MWF).

StrucSoft Solutions is applauded for being a software developer with clout.

A word, please George

It is little wonder then that Cindy Posimani, head of Howick’s marketing and export division, has long been a George Ajami fan – Howick has been working with StrucSoft Solutions since 2006. She was thrilled to get to chat with the man himself, whom she describes as a “great leader of a fantastic team”, and to hear him impart some of his wisdom. It was timely, given StrucSoft Solution’s recent (April 2021) acquisition by The Graitec Group.

George Ajami at a tradeshow

The start of StrucSoft Solutions

George’s original company was founded in 1994 and called Pro Steel. The company had a focus on an AutoCAD-based steel detailing software.

Individual customer demand drove developments.

Says George: One of our early customers in 2000 told us he had three roll-formers and could we write him a roll-former panel programme? We did and called it ProStud (it was an AutoClad architectural-based wall panelizer). Someone else rang and said he liked what we had done for the other customer and could he use the same software, but it needed trusses included, and so we added trusses to it. Then someone called and also said he really liked what we did and he had a selection of Howick machines. We wrote an interface and that is when our relationship started with Howick, about 16 years ago.

In 2008, George sold the AutoCAD-based software business and started StrucSoft Solutions with a handful of talented staff that quickly grew over the years… as did the customer base. An early appointee was a programmer tasked with creating a compatible software to Revit®. The programmer came up with a proof of concept which George sold successfully to the market.

“StrucSoft Solutions would not be what it is without the help and collaboration of our employees.”

The snowballing of StrucSoft Solutions

George had no idea that the floodgates would open in StrucSoft Solutions infancy. He thought the people he was targeting were currently “non-existent” due to the economic collapse of 2008-2010. What he did not realise was that there was a “whole crop of customers” he did not even know existed. This was due to a change in earthquake laws in California that meant non-structural walls and ceilings had to conform to completely new codes.

Says George: Buildings, like hospitals, had to be gutted out and walls and ceilings had to be redone. This was our area. At the same time, those wonderful decision makers said everything had to be done in Revit®. I mean, it was like a perfect storm. So, within weeks of releasing our new software a whole bunch of people called us – large companies like DPR Construction and KHS&S. We ended up with 35 customers the first year, all of whom started using what we had and then suggesting additions. We built the next version, which is MWF Pro Wall, which was in response to market demand and was the first step we took to what we have today.

MWF is built upon the Autodesk Revit® platform, automating the creation of both light gauge steel and wood panels, completing the link from design to manufacturing.

George says the next big step for his company came in 2015-16 with the new drive toward more automation, called Industrialised Construction. This was not difficult for StrucSoft Solutions to achieve, thanks to the Autodesk Revit® platform.

Says George: Once the call came out for Industrialised Construction, we were very ready for this in the sense we already had a foot in the door and jumped on it.

Hello to ONYX

But Revit®, in George’s mind, was not perfect. He talks of finding constraints. He, and his team, believed its strength was in the details, but those details also weighed and slowed the platform down. As Revit® connected with everything in a building (materials, electrical and plumbing, etc, details) this meant a lot of calculations were required every time something was changed. And thus, this strength also became an Achilles heel, George says. How to solve this? A lightbulb moment came thanks to the gaming community.

Says George: My Eureka moment arrived when I met a friend for coffee and to play backgammon. He had a teenager playing games (on a screen) and there was great quality of graphics in those games. I was blown away. I went to the office and said, guys why don’t we think of gaming engines.

And so, ONYX was born – integrated with Revit®, it sits in the Cloud. It manages data, just-in-time processes and any manufacturing information data can be represented with good visibility.

Welcome to The Graitec Group

StrucSoft Solutions is now part of the Graitec Group, thanks to an acquisition that occurred in April 2021.

While StrucSoft is very strong in North America, George felt the time had come for the company to spread its wings. When word was out that StrucSoft was looking for an investor, the phone rang hot – a testament to the strength of the company.

The obvious investor, ticking many boxes, was The Graitec Group, an international BIM, fabrication and design software developer (for AEC, and Autodesk Platinum Partner across Europe and Gold Partner across Canada, USA and Russia). The acquisition means not only strong resources worldwide, but continuity for the company. And, from a technological point of view, Graitec and StrucSoft share the same strong DNA.

Says George: We need a physical presence elsewhere and that means investment, finding people and infrastructure. With the backing of a company like The Graitec Group we can get there much, much faster. There are lots of similarities between the two companies. Our combined teams will be able to better service our customers and push the boundaries of what our software can achieve in the manufacturing and AEC sectors. The acquisition didn’t happen overnight – it was a long (three year) dating process. For me it was important to create continuity for StrucSoft Solutions, for the team and for the product.

StrucSoft Solutions’ MWF (Metal Wood Framer) software completes the functional coverage of Graitec’s FABRICATE offering by adding light gauge steel and wood to existing rebar, prefabricated concrete and structural steel. End to end solutions for the construction industry, and many happy customers, is the result.

Was this article insightful? Share it

June 2021 #Features