Why Howick

Part of the Solution

There is a major problem globally with the cost of housing, so the construction industry is striving for better, smarter ways of doing things. At Howick, we see ourselves as part of the solution. If we get it right, we will help create a better place for everyone.

We manufacture precision roll-forming machines and technology for light steel framing. For nearly 50 years we have been innovating in this space, creating systems and machines that are now employed by construction businesses in 80 countries the world over. We are proud of the formidable reputation we have built up over that time for performance, reliability and service.

Proudly New Zealand Made

Unique in our sector, Howick steel roll-forming systems are 100% manufactured at our plant in east Auckland, with top quality New Zealand-made componentry either made in at the Howick factory or sourced locally.

We are so confident in the quality and performance of our machines, and of the support we provide, that we offer a unique guarantee. If you are not truly satisfied with your Howick FRAMA™ 3200 or 5600 system after its first six months of operation, return it to us and we will refund 100% of the machine purchase price*.

Free rolling with Howick

Unlike competing products, with a Howick system there are no meterage rates. This means you can run as much steel as required once you own the machine, and you pay zero in the way of toll-to-roll fees. This type of fee can make a big difference to the whole-life operating costs and the returns you make on your investment, so worth looking out for!

And no Howick software fees!

Specifically designed for frame manufacturers, our machines will receive data from any partnered CAD framing package. Because they come with an open language control system you pay no licence fees to Howick. You are free to pair your machine with your software of choice. If you already work with an existing CAD system, it means an easier transition and keeps things simple for you and your team. If you are not working with an existing system, that is fine – talk to us and we will help you select the best option for your needs.

Unique features include true load-bearing joints

Howick customers benefit from precision accuracy, so things like re-work and wastage are kept to the absolute minimum. As an example, all punching and fixing holes are placed through pinpoint accurate computer control. As well as ensuring that frames and trusses are manufactured with extreme precision, this also means they can be self-locating and jigging, saving time and improving efficiency.

What is more, features like our unique end bearing stud details enable the construction of load-bearing frames for multi-storeyed structures, making Howick technology the most advanced framing systems available. To find out more, connect with us today.

Team Howick

NZ and Global Sales

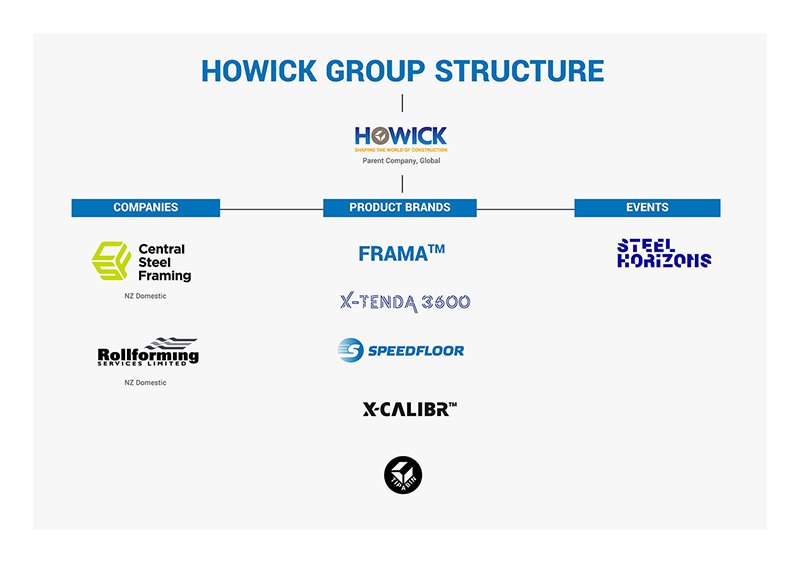

Howick Group Structure

Howick Group is a multi-faceted light-steel framing solutions business that spans several innovative companies, products, and even an international industry event.

FAQs

Buying a steel framing machine is a big step towards scaling your construction capabilities. But how do you ensure you are making the right choice? The best way to avoid the common pitfalls is to ask some practical questions upfront about build quality, software compatibility, ongoing support, transportability and sustainability.

Howick systems are engineered for precision, producing components that are accurate to within +/- 0.5 mm. Our machines feature true-end-bearing detail. Exclusive to Howick machines, this feature crimps in the radius on the stud profile, so studs sit perfectly flat into the top and bottom tracks of a panel. This single feature reduces vertical shrinkage and eliminates shear stress on screws. The result is improved structural integrity of your builds. This level of precision has many benefits. It speeds up assembly, improves the overall quality of construction, and reduces the need for rework. Ultimately, Howick’s high-precision machines save build time, minimise waste and cut construction costs.

Yes. Howick machines are compatible with a wide range of industry-standard CAD framing software platforms including Autodesk, Strucsoft, Tekla, Vertex, FrameBuilder-MRD, Dynamo, StudFinder, and many more. You are free to choose the design platform that best suits your workflow and your clients.

No. Howick machines have open language control systems and are roll toll free. You do not pay Howick software licensing fees, royalties, or usage-based tolls to run your machine. You own your system outright and maintain full control of your operation.

Howick machines are designed for durability and ease of maintenance. Most regular maintenance tasks can be carried out in-house by your team. We also offer global parts supply, technical support, and service plans to ensure maximum uptime.

Every new roll-forming machine comes with comprehensive training tailored to your team. From machine setup and operation to file conversion and output testing, we make sure your team is confident and capable from day one. We also offer ongoing support as your operation grows.

Yes, multi-profile steel roll-forming machines are available. These are designed to handle multiple profile configurations, allowing you to switch between profiles with minimal changeover time. These systems offer additional versatility and flexibility in your production capability offerings.

We do also offer dedicated machines which are engineered to produce a specific profile. These systems are best for high-volume production with consistent quality and precision.

Howick machines are designed to maximise throughput, reduce labour, and improve accuracy. For most customers, this translates into a rapid return on investment, especially when building at scale or operating in labour-constrained environments.

With machines operating in over 80 countries, we provide responsive global support. We have regional representatives in key markets including the USA, UK, EU and Australasia. Together with our extensive in-house service team, we offer in-person or remote troubleshooting, training and a priority turnaround on ex-factory parts if the need should arise to keep your line running smoothly. We also encourage customers to maintain a good level of consumables in stock to keep machine downtime to the minimum.

Every Howick machine is designed, engineered, and built at our dedicated manufacturing facility in Auckland, New Zealand. We also assemble everything in our Auckland plant, where our team of highly trained specialists bring years of experience and meticulous attention to each job.

This gives us the advantage of tremendous quality control. We have oversight of our complete supply chain, systems and processes, ensuring a level of reliability and performance that sets our technology apart.

By keeping everything under one roof, we can swiftly adapt to your needs, incorporate your customisations, and reduce the risk of supply chain disruptions. Because of this, we can provide industry-leading levels of uptime for our systems and quality guarantees that are unique in the sector.

Download the updated Howick Machine Buyer Guide 2025 to compare features, build types, and ROI considerations in one place.

Work with us

We are a successful family owned and operated business. As such, family values and a real can-do Kiwi ingenuity define our culture. Howick is helping to shape the future of construction globally. We are an internationally recognised, industry-leading company that is committed to education, training and developing opportunities for our team to expand and diversify their experience. If you see yourself as forward thinking, eager to learn and you want to be part of a growing game-changer, we’d love to hear from you.

Eco Statement

If we are to be part of the solution for a construction industry solving a global housing supply issue, it is fundamental that we take responsibility for sustainable framing manufacture. Our machines employ everything from energy efficient drive motors that surpass EFF1 requirements, to auto-off switches and EMC filters to minimise environmental impact. That is just the start. Sustainability for us is about a reduced overall carbon footprint, maximised recycling capability and optimized energy efficiency. That is better for the environment, and it is great for your bottom-line too.

Engineering & Design Services Directory

There is a number of companies globally with experience in Howick technology. If you are looking for support with engineering and design services using light steel framing, here’s some of the organisations we have worked with and know of who may be able to help.

Why Build with Light Gauge Steel

Light gauge steel, or LGS (also known as cold formed steel), framing has become the preferred option for many of the world's leading construction companies, and it is not surprising why. There are so many arguments in favour of LGS framing and below Howick shares with you some of the most compelling facts and figures to ponder.

Innovation

Innovation is part of the Howick creation story. Since our foundation in 1978, in true Kiwi style we have applied creative thinking with engineering nous to solve challenging, technical problems. Coupled with a focus on continuous improvement, it is a mindset that has helped Howick become a leader in light gauge steel framing automation with a global reputation for innovation, quality and steely reliability.