TH200 Tophat Batten

- Gauge Range

-

- Production Speed

-

- Dimensions L x W x H

-

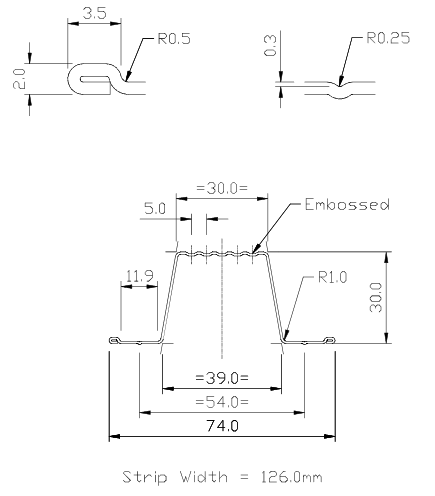

The TH200 produces a tophat batten up to 0.75mm (24 gauge) thickness. The profile has been specially developed for material efficiency with a screw location groove and a rolled safety edge.

All hardware is CE and UL compliant and tested to comply with current CE emissions standards.

- One of the main advantages of using steel battens is that they are dimensionally accurate and stable. This means that you can achieve a higher quality finish in lined walls and ceilings without the need to return to site to repair any, once the building has settled

- Tophat roof battens nest together for easy transportation negating movement cracks

- Cut to length reduces wastage and site cutting

- The FRAMA machine control allows for room and building lots to be loaded using our CSV format

- Batch marking is possible with the optional inkjet printer

- Spans up to 900mm at 900mm spacing or 1200mm at 370mm spacing

- Can be used in extra high wind and in snow load situations

- Lightweight 0.836 KG per metre

- Dimensionally stable, battens expand and contract at 0.1% the same rate as the roof in extreme temperature changes

- Steel battens don’t absorb moisture

- No more buckling ridge line flashings

- Battens can be fitted to both timber and steel trusses or rafters.

- 100% recyclable

| TH 200 | ||

| Material Range | 0.75mm | 24 Gauge |

| Product Size | 30mm x 30mm Ceiling Batten | |

| Product Rate | 1500m/hour | 4900 feet/hour |

| Control | FRAMA machine control | |

| Length | 1900mm | 6'2" |

| Width | 500mm | 1'8" |

| Height | 1260mm | 4'2" |

| Weight | 1125kg | 2475lb |

| Electrical Req. | 400 - 460V | 50 - 60Hz |

| Motor Power | 4.0kW | 5.4hp |

| Hydraulic Power | 1.1kW | 1.5hp |

| Hydraulic Tank | 5 litres | 1.3 gal |

| Cover | Fully Guarded with Emergency Stop Buttons | |

| Decoiler | ||

| 1.5T Decoiler | 3300lb Decoiler | |

| Dimensions L X W X H | 1.05m x 1.2m x 1.68m | 3.4' x 6.6' x 5.5' |

| Weight | 350kg | 770lb |

| Drive Motor | 2.2kW | 3hp |

| Jaws | 3 Jaw Self Centring | |

| Jaw Expansion | Hydraulic | |

| Jaw Expansion Range | 480mm - 520mm | 1' 7'' - 1' 8 1/2'' |

| Speed Control | Dancer Arm with Inclinometer | |

| Auto pause at coil end | ||

| Max Coil Weight | 1500kg | 3300lb |

| Max Coil Width | 200mm | 8'' |

| Mac Coil OD | 1500mm | 59'' |

| Nominal Bore | 508mm | 20'' |

| Safety | CE, UL, Cat 3 Compliant | |

|

* Production Speed will vary due to component complexity. Howick Ltd Reserve the right to update the machine specification without notice. |

||

Ceiling Battens

| 30x74x0.55 Top Hat Section Refer: AS/NZS1170 Loadings code also NZS3604:2011 Design to AS/NZS4600 Light Gauge Steel using G250 grade steel |

Ceilings with 0.5kPa Live load Table of max span vs spacings Figs based on max deflection L/500 Connect with min 2 - 10 gauge screws for centres noted |

|||||

|

|

Section Spacings (mm) |

|||||

| Connect with min 2-10 gauge screws for spans as noted | 400 | 400 | 450 | 450 | 600 | 600 |

| Connect with min 1-10 gauge screw for up to 1.0m span | Span (m) | Max Point Load (kN) | Span (m) | Max Point Load (kN) | Span (m) | Max Point Load (kN) |

| Max distributed loads kN/m | 0.200 | 0.225 | 0.300 | |||

| Using 10mm gib ceilings | 1.7 | 0.25 | 1.5 | 0.33 | 1.4 | 0.35 |

| Using 13mm gib ceilings | 1.5 | 0.33 | 1.4 | 0.35 | 1.3 | 0.38 |

| Using 16mm gib ceilings | 1.4 | 0.35 | 1.4 | 0.35 | 1.2 | 0.41 |

| Using 20mm gib ceilings | 1.3 | 0.38 | 1.3 | 0.38 | 1.2 | 0.41 |

CEILING BATTENS

| 30x74x0.75 Top Hat Section Ceilings with 0.5kPa Live load Figs based on max deflection L/500 |

Table of max span vs spacings. Connect with min 2 - 10 gauge screws for centres noted | |||||

|

|

Section Spacings (mm) |

|||||

| Connect with min 2-10 gauge screws for spans as noted | 400 | 450 | 600 | |||

| Connect with min 1-10 gauge screw for up to 1.0m span | Span (m) | Max Point Load (kN) | Span (m) | Max Point Load (kN) | Span (m) | Max Point Load (kN) |

| Max distributed loads kN/m | 0.200 | 0.225 | 0.300 | |||

| Using 10mm gib ceilings | 1.8 | 0.60 | 1.7 | 0.65 | 1.5 | 0.75 |

| Using 13mm gib ceilings | 1.7 | 0.65 | 1.6 | 0.70 | 1.5 | 0.75 |

| Using 16mm gib ceilings | 1.6 | 0.70 | 1.5 | 0.75 | 1.4 | 0.80 |

| Using 20mm gib ceilings | 1.5 | 0.75 | 1.4 | 0.80 | 1.3 | 0.86 |

Battens for Roof and Wall claddings

| 30x74x0.75 Top Hat Section Propriatary steel roofings with wind loads Or 0.25 LL whichever worst case |

Table of max span vs spacings. Pressure Factor Cp = + or - 0.9 | |||||

|

|

Section Spacings (mm) |

|||||

| For connections to wood substrate refer NZS3604:2011 for wind loadings. For connections to min 0.75 ga steel | 600 | 600 | 900 | 900 | 1200 | 1200 |

| Connect with min 1 - 10 gauge screw for up to 0.50kN/m, 2 per 1.0kN/m, 3 per 1.5kN/m, and 4 per 2.0kN/m | Max Span (m) | Max UDL (kN/m) | Max Span (m) | Max UDL (kN/m) | Max Span (m) | Max UDL (kN/m) |

| Medium wind 37m/s | 1.2 | 0.44 | 1.1 | 0.66 | 1.0 | 0.88 |

| High wind 44m/s | 1.2 | 0.63 | 1.0 | 0.95 | 0.9 | 1.26 |

| Very high wind 50m/s | 1.1 | 0.81 | 0.9 | 1.22 | 0.8 | 1.62 |

| Extra high wind 55m/s | 1.0 | 0.98 | 0.9 | 1.47 | 0.8 | 1.96 |

Note: All fixing types are determined as required for the higher uplift loads at the periphery of the roof (based on local pressure factors in AS/NZS 1170.2)