Connex Offsite

Established in 2017, Connex Offsite can essentially be considered a new kid on the block. Yet this company, with its focus on manufacturing bathroom pods, has not wasted any time crawling around. It is all systems go, with operations very much in growth mode, and the world sitting up and taking notice. Just this year, Connex Offsite created an additional 50 jobs in Newry (where the company is based) as part of a £4.6million investment to assist with projected growth in international markets.

Background

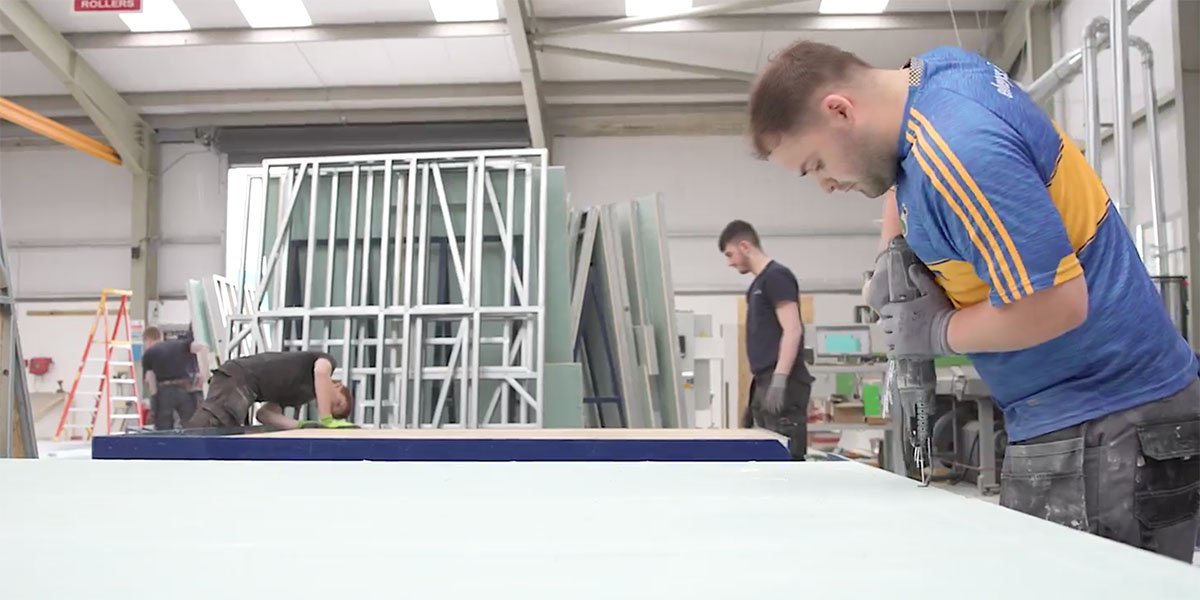

Based in Northern Ireland, Connex Offsite specialises in the manufacture of high-end modular bathroom pods for installation by the construction industry. With framing made of light gauge steel, the pods are an impressive product grown out of a marriage of innovative and flexible design, construction knowledge and manufacturing excellence. The result - a product with great customer acceptance that is attracting attention from various parts of the world.

The pods are completely finished, walk-in bathrooms that are shrink wrapped on the factory floor and shipped to the construction site.

Invest Northern Ireland Chief Executive Kevin Holland describes Connex Offsite as an “early-stage SME that has achieved remarkable success”.

Why offsite?

The beauty of pods is they can be manufactured offsite and transported to construction sites.

Connex Offsite recognises that taking the most labour-intensive tasks away from the construction site makes perfect sense. The 70:60:30 is adhered to and explained to clients – that is: if you pre-manufacture 70 per cent of the project, you reduce your workforce by 60 per cent and the schedule by 30 per cent.

Connex Offsite Managing Director Brendan Doherty says traditional methods need to be modernised to get more value out of labour and tradespeople.

“To do this we need to move as much of the construction project to a factory and manufacture instead of build so you can then streamline the process and multiply the output with the same resources.

“Off-site manufacturing is one of the fastest growing modern methods of building in the UK and is being embraced by the construction industry,” says Brendan who can also add plenty of other positives.

“It demands faster delivery of product into production lines, in some cases up to 20 times faster than traditional construction. So, not only are we reducing costs and saving man hours, we are also manufacturing a better-quality product and providing a controlled environment that is safe and warm and therefore a more pleasant place for our staff to work in.”

Brendan Doherty, MD of Connex Offsite

Howick connection

Connex Offsite’s embrace of offsite manufacturing is in sync with Howick’s. Both see the value of the pre-fabricated or pre-manufactured product. Brendan is a firm believer in offsite manufacturing being one of the fastest growing modern methods of building in the United Kingdom.

The connection between Howick and Connex is more tangible than this shared appreciation of offsite manufacturing. Connex Offsite’s 25,000 square feet factory also houses the Howick FRAMA™ 3200, which is key in the manufacture of the framing for the bathroom pods.

Growing client base

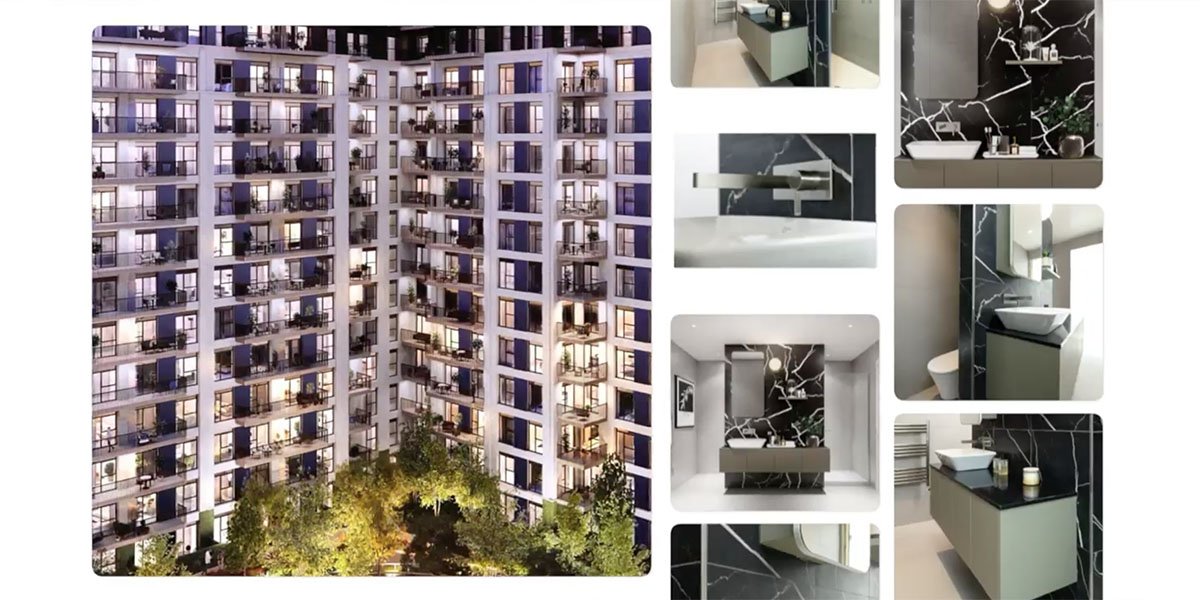

The Connex Offsite team has manufactured more than 200,000 bathroom pods for a variety of clients. Their bathroom pods can be found in hotels (such as the Hilton, Marriott and Holiday Inn), student accommodation, healthcare facilities and residential markets.

Connex Offsite’s services are proving very attractive, for example, to companies such as London based property developer Mount Anvil; with a recent £3million contract secured to deliver pods for its Royal Eden Docks scheme in London.

“This new investment and expansion of our team will help us build on our London success and target opportunities in the high rise residential, hotel and student accommodation sectors, particularly in Great Britain and the Republic of Ireland markets whilst also exploring opportunities in North America,” added Brendan.

|

|

Times ahead

Brendan is a fast-paced operator. He talks of how he got his company out of the gates at “100 miles an hour”. There is no desire to slow. The aim is for Connex Offsite to be a global pod supplier.

“It is great to see the product we made in a small area of Northern Ireland supplied into some of the largest cities in the world. We are established in the UK and Ireland and want to grow that market but also want to conquer the American market and become a global pod supplier,” he enthuses.

As part of its overall strategy, Connex Offsite has undertaken extensive market development activities and implemented new software systems to boost its competitiveness. The company has invested in state-of-the-art equipment to maximise its operational capacity and is growing staff numbers and its international reach too.

Just this year the company announced its “ambitious five-year growth strategy” aimed to position it as the premier UK supplier of bathroom pods. Covid-19 has done little to impede growth plans. In fact, it has led to huge growth, Brendon reports, due to the fact it forced restrictions on the level of labour on a construction site. That has been a catalyst for a shift to modular construction, with the pods completely finished in a controlled environment.

Overall, the order book is increasing. This new kid on the block is growing into something spectacular.