STEEL HORIZONS | TAMPA: The IKEA of Construction – inside M3 Components’ scalable offsite model

⏱️ 2 min read

What if putting up a hospital was as smooth as assembling a flat-pack kitchen? Could large-scale building ever be as repeatable and predictable as an IKEA experience?

Welcome to the STEEL HORIZONS Speaker Spotlight, where we break down the most thought-provoking moments from the Tampa event and explore what they mean for the world of construction.

Offsite construction is evolving quickly, and manufacturers need operational models that can scale and deliver consistent results. In this presentation, M3 Components Innovations Manager Lorenzo Petrini shared how the company aims to become "the IKEA of construction" by blending repeatable systems with customisable designs. Here is how M3 Components is making that vision a reality.

Repeatable systems, flexible outcomes

M3 Components is an arm of Mark III Construction, a family-owned construction company incorporating three distinct divisions; M3 Components, M3 MEP and M3 Service. The group employs around 330 people across these three separate divisions.

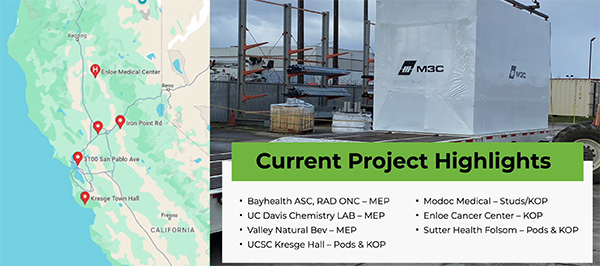

Operating from a 24,000 square-foot manufacturing facility in Sacramento, California, M3 Components specialises in producing modular wall panels, pods, and modules for the healthcare and education sectors.

When Lorenzo joined two years ago, the Components factory was practically a blank slate. These days? It is bursting at the seams, with plans underway for a new facility that will have three times the area.

The growth has not been by accident. It is the result of focusing on developing an “alternative construction solution” that is faster and cheaper, without compromising quality or design, says Lorenzo.

"We are still a little bit far away from being an IKEA of construction. But we hope to get there."

Designing out inefficiency with common sense LEAN

At M3 Components, efficiency is baked into the operation with LEAN principles. Rather than react to problems, the team work hard to design them out from the get-go.

"When I explain this to the people on the floor, I always talk about common sense," he says. “When you move into your brand new house, I don’t think you’re going to put your cutting knife in the bathroom.”

Adopting this "common sense" approach to LEAN has led the team to redesign their manufacturing floor layout with U-shaped and L-shaped workstations. It has also opened the door to unconventional innovations, like assembling framing vertically.

"We made an entire system of rolling walls and rolling vertical tables where we can achieve better flow, better numbers, even if we have only a 24,000 square foot facility.”

The result? Smoother movement, fewer steps, and a big uptick in output.

Two LEAN tools drive continuous improvement

A big part of creating this culture of continuous improvement is giving the team the tools to speak up, in a positive way.

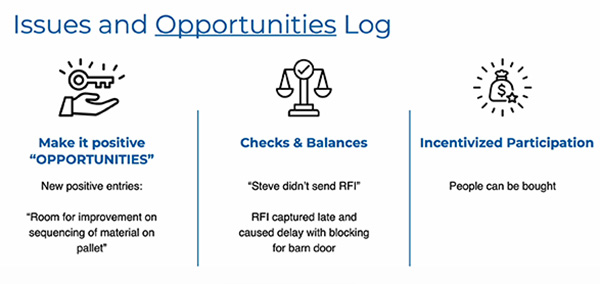

- Issues and Opportunities Log: A log allowing every team member to flag problems or suggest new ideas. This encourages a culture of open communication and proactive problem-solving, systematically identifying areas for improvement (rather than focusing on failures or mistakes).

- Lessons Learned Sessions: These sessions happen at key project milestones and involve reviewing the Issues and Opportunities Log and gathering team-wide feedback. This approach helps capture what went well and where things can improve.

Together, these tools create a feedback loop that captures knowledge and folds it back into the system, so every project is sharper than the one before. Significantly, the focus is on opportunities, not failures.

Virtual Design and Construction - one seamless workflow from model to machine

Of course, the technology side is just as important, and Virtual Design and Construction (VDC) has become central to M3 Components’ success.

"70% of our work is now fully digital and paper‑free," Lorenzo says.

With VDC, the team builds a precise 3D model of every component before a single piece of steel is cut. That model becomes the single source of truth for design, procurement, fabrication and installation.

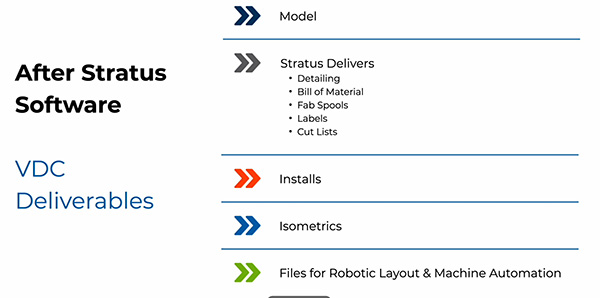

Bridging that digital world with actual fabrication is Stratus - a fabrication-management platform that translates designs into practical production details for machines like their Howick FRAMATM 7600. With accurate cut lists, labels, CNC files, QR codes and live dashboards, everything is seamlessly coordinated.

Connecting virtual design and precise machinery in a single, seamless workflow helps reduce waste and accelerate production cycles. It is a key component of M3 Components' Zero-Defect Initiative.

Customers get a real-time view of projects

In addition to streamlining every aspect of production and delivery, Stratus enhances the customer experience by providing clients with a real-time view of their project's progress.

"I have really good feedback from our customers because I was able to give them access to our dashboards so that they can see exactly where we are at with each product. Everything we produce is online."

This real-time transparency helps clients to make informed decisions quickly and builds confidence in the team and the process.

Scaling up into the future

M3 Components sees huge potential for growth and is already looking to expand its capacity, starting with another Howick FRAMATM 7600. While there are geographic limitations currently, they are actively eyeing opportunities in other states, and ways to sustainably grow their winning formula.

"The sky is the limit," Lorenzo says.

Building fast and keeping costs down are part of the equation at M3 Components, but the bigger story here is their commitment to developing a smarter operational model that can scale up and drive long-term success.

Want to explore more insights like this one? Browse the full STEEL HORIZONS Speaker Series, or talk to us about how we can support your next offsite project.