STEEL HORIZONS | TAMPA: Rethinking modular operational models with Jim Gabriel

⏱️ 2 min read

Modular construction might be the future, but how do businesses ensure that their operational model is not just capable, but scalable?

Welcome to the STEEL HORIZONS speaker spotlight where we break down the most thought-provoking moments from the Tampa event - and explore what they mean for the world of construction.

This time, Jim Gabriel, President and CEO of MODLOGIQ and DESIGNLOGIQ, shares his perspective on how offsite construction can best scale and succeed. Leveraging over 45 years of experience delivering customised modular construction for healthcare, education, and commercial sectors, MODLOGIQ has developed a process-driven approach that challenges the traditional factory-first mindset. Now, they want to use what they have learned to help solve the housing shortage.

Why scalability is a challenge for traditional modular

“The current model is not scalable and, candidly, it’s not sustainable.”

Jim did not mince words when describing what he saw as a fundamental problem with the current model for modular construction.

Modular manufacturers often struggle because the traditional model demands a high upfront investment with significant overheads, but can produce a slow ROI, he says.

The main cause of this frustration is an inability to scale effectively. When all your expertise, resources and production capability are locked to a single location, it is difficult to apply the same model across new regions without replicating everything from scratch.

This pressure pushes modular builders to chase large, geographically convenient contracts and limits their ability to respond to real world demand.

Shifting focus from factory first to assembly first

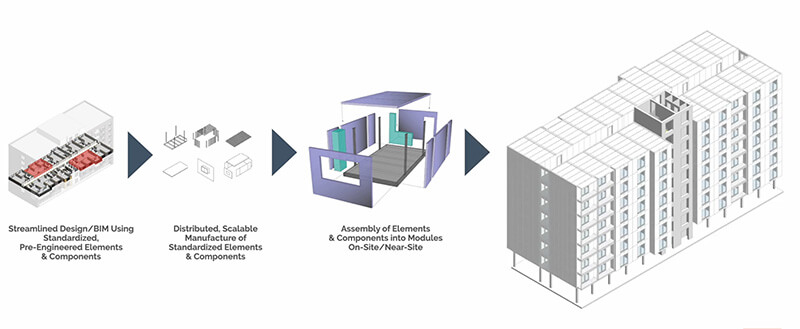

MODLOGIQ’s approach represents a fundamental shift in thinking from a traditional factory first mindset to an assembly first model.

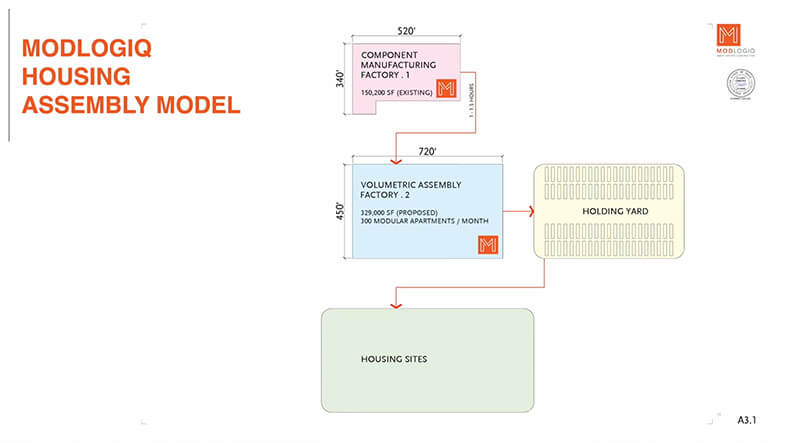

Framing and sub-assemblies for a project are produced at a central manufacturing facility, but not assembled. Instead, the facility acts as a component hub, supplying different volumetric assembly operations, strategically situated closer to target markets.

These volumetric facilities are designed for flexibility, and focus on efficient assembly and delivering customisation to meet specific project requirements.

As Jim Gabriel explains,

“If you come to our New Holland operation, it is decidedly unautomated, but it is entirely portable.”

This adaptability is key to MODLOGIQ’s scalability. By separating component manufacturing from final assembly, they can expand capacity and reach without duplicating heavy infrastructure in every region. It is an approach that maintains efficiency, consistency, and profitability as they grow.

What assembly first means for design

A key advantage of MODLOGIQ’s process is its ability to balance repeatability with design flexibility.

Instead of prescribing fixed layouts, the system allows design teams to select from a standardised kit-of-parts, and then arrange, reconfigure or modify as needed. Or as MODLOGIQ’s Chief Innovation Officer Chris Mortensen, puts it:

“Standardise the invisible, customise the visible.”

The goal is to also standardise mechanical, electrical and plumbing (MEP) elements and turn those components into another kit-of-parts.

By integrating MEPs into a modular, repeatable process, MODLOGIQ can complete more aspects of the build in a controlled offsite environment, rather than relying on multiple subcontractors onsite.

Learning from the demands of healthcare construction

This model is not just theory, and MODLOGIQ has already used it to deliver complex, real-world projects. This includes delivering the largest modular permanent healthcare facility in North America, built using offsite construction.

By using standardised systems to produce customised designs, the team has been able to meet the strict demands of a healthcare build. It is a clear example of how assembly-first thinking can perform in one of the most demanding construction environments.

From hospitals to housing: Where we are heading next

The healthcare sector has forced MODLOGIQ to solve some of the toughest offsite challenges, including repeatability, compliance, and site coordination. It is experience that is directly relevant to the housing sector.

“If modular is going to help solve the affordable housing challenges that we have, we've got to be able to find more efficient ways to build."

For Jim, the future of modular is clear: Think beyond factories. Think in kits, think in assemblies, and above all, think in processes that can scale, flex and deliver consistently.

"Modular can do big things. What we're now working on is how do we apply that to bigger challenges, not just bigger projects, with a higher level of complexity."

It is not just about building faster structures. It is about building smarter operational models that are both scalable and financially sustainable.

Want to explore more insights like this one? Browse the full STEEL HORIZONS Speaker Series.