From workshop to worksite: How X-CALIBR™ transforms large span portal construction

⏱️ 4 min read

For more than three decades, Arc Engineering director Matt Nash has been chasing smarter, faster ways to build agricultural and rural buildings. So when our sister company, Central Steel Framing (CSF) introduced X-CALIBR™ to the New Zealand market in 2022, he was quick to trial it. X-CALIBR™ is a prefabricated structural solution for large span portal construction, developed by Howick and exclusively available through CSF (and only in New Zealand at present). In this interview, Matt talks through what changed when his team put the technology to work, including:

-

how prefabricated sections cut weeks from programmes

-

how better coating protection supports long life

-

why that speed brings forward return on investment for clients.

Watch the full interview with Matt here.

Cutting steel portal construction times for dairy sheds by more than 25%

Arc Engineering is a Taupō-based firm that specialises in agricultural and rural infrastructure projects. With an eye for practicality and efficiency, they have always been quick to explore new technology that produces better outcomes and had keenly followed the development of X-CALIBR™.

When X-CALIBR™ launched, they were among the first to trial it, and it has not disappointed.

“Traditionally, if you had a very good crew of guys, you would build a dairy shed over 16 weeks,” Matt explains.

“With the X-CALIBR™ system as part of the build process that we have designed, we can shorten that build process to 10 to 12 weeks.”

The Arc team also discovered that far less background work was needed. Instead of starting fabrication months in advance, they could now go from fabrication to a standing shed in just two weeks. Being able to move at this speed opened up new opportunities that were previously unimaginable.

The system behind the speed

Designed from the ground up to simplify construction, the X‑CALIBR™ system uses precision roll‑forming to produce strong, lightweight steel members - rafters, columns, purlins, girts, and more - without the need for onsite drilling, cutting, welding, or measuring.

"When the X-CALIBR™ product arrives from the factory, all the bracketry comes already pre-assembled. All the knee joints are pretty much pre-assembled. All you've got to do is rivet off your main rivets on your sections to make your gables up, which is pretty quick," says Matt.

That means crews can align and install frames in hours instead of days, with minimal adjustments and fewer workers. This streamlined process slashes waste, improves site safety, and accelerates schedules.

While Arc’s focus is on agriculture and wintering barns, any sector that requires large span, durable structures stands to benefit. The same technology that improves barns also improves warehouses, cold stores, logistics hubs, and modular facilities.

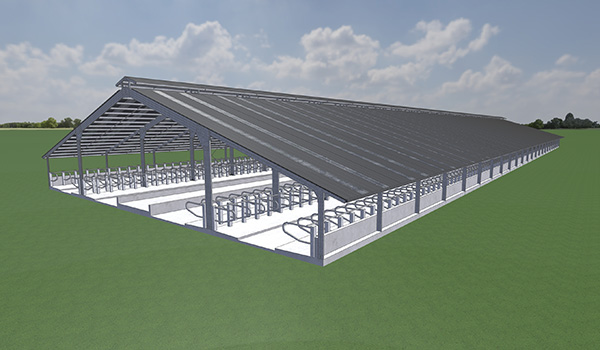

Rendered image of wintering barn courtesy of Central Steel Framing

Durability that builds confidence

While the speed of X-CALIBR™ stands out, for Matt, it is also the quality of the materials that he values. Unlike many alternatives that use standard Z250 coatings, X-CALIBR™ steel features a Z450 zinc coating, which almost doubles the protection against corrosion.

The higher zinc content extends the lifespan of the structure, reduces maintenance costs, and provides clients with the reassurance that their investment will endure.

Return on investment, delivered sooner

Alongside its durability, the compressed timelines also help reduce the financial risk for Arc Engineering’s clients. Faster completion brings forward revenue and makes the building productive earlier.

In fact, the only negative comment Matt has heard about X-CALIBR™ was a passing remark from one of his competitors, who had also trialled it:

"The only comment that he could put forward that he didn’t like about the X-CALIBR™ product is that it went up too fast and there was no money in it for him!"

For clients, however, that is the very point.

“From the start to the finish, that process is a lot quicker,” Matt says. “So the farmers can get into their product a lot quicker and start getting a return on their investment.”

Howick technology proven by Arc Engineering

For Matt, the attraction of X-CALIBR™ is straightforward. It enables his company to build faster, deliver greater value to clients, and have confidence that the results will last. For Howick, his story is proof of what can be achieved when we push the boundaries of roll-forming technology and get these latest innovations into the hands of forward-thinking builders.

Technology only matters when it helps people deliver. Matt Nash and Arc Engineering show how the X-CALIBR™ system turns that promise into real gains onsite.

As mentioned, X-CALIBR™ is currently only available in New Zealand through Howick’s sister company, Central Steel Framing.